Car

How biomechanics transformed Joe Gibbs Racing's NASCAR pitstops

by Samarth Kanal

5min read

Pitstops are one of the biggest performance differentiators in motorsport, where saving seconds in the pits can lead to bigger payoffs on the track. In a series such as NASCAR, where the cars are largely built to the same specification, pitstops arguably play an even more essential role.

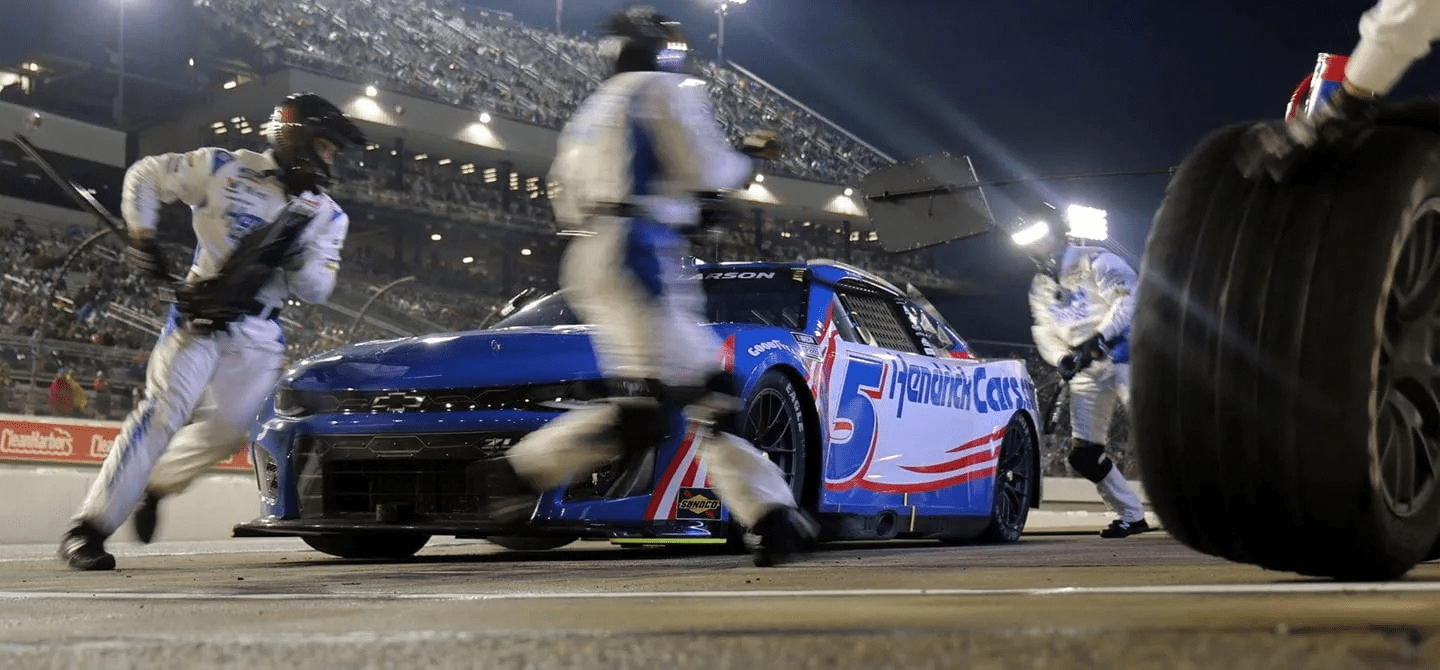

Pitcrew members in action getting ready to change the left-hand side tyres at JGHPI lab

How JGHPI applies biomechanics to NASCAR pitstops

JGHPI works just outside Charlotte, North Carolina – on site at JGR's NASCAR headquarters – from a laboratory that can fit a full-size NASCAR car and its pitcrew.

Visual data isn’t captured using motion capture suits or reflective markers, as those are too restrictive towards movement. Instead, the laboratory is fitted with more than 40 high-speed cameras that track the movements of every joint on an athlete’s body from 2D video coupled with advancements in AI. The data from each pitstop comes to terabytes of video per hour. Every hundredth of a second the lab collects dozens of data points, forming a complete picture of how each part of the athlete’s body is moving and transferring forces.

While Formula 1 pit athletes are dedicated to each corner of the car, NASCAR tyre changers, tyre carriers, fuelers, and jack people work on both sides of the car

Many NASCAR pitcrew members stem from baseball, although American football and basketball also make up a large proportion of NASCAR athletes

Why Joe Gibbs Racing prioritised optimising NASCAR pitstops

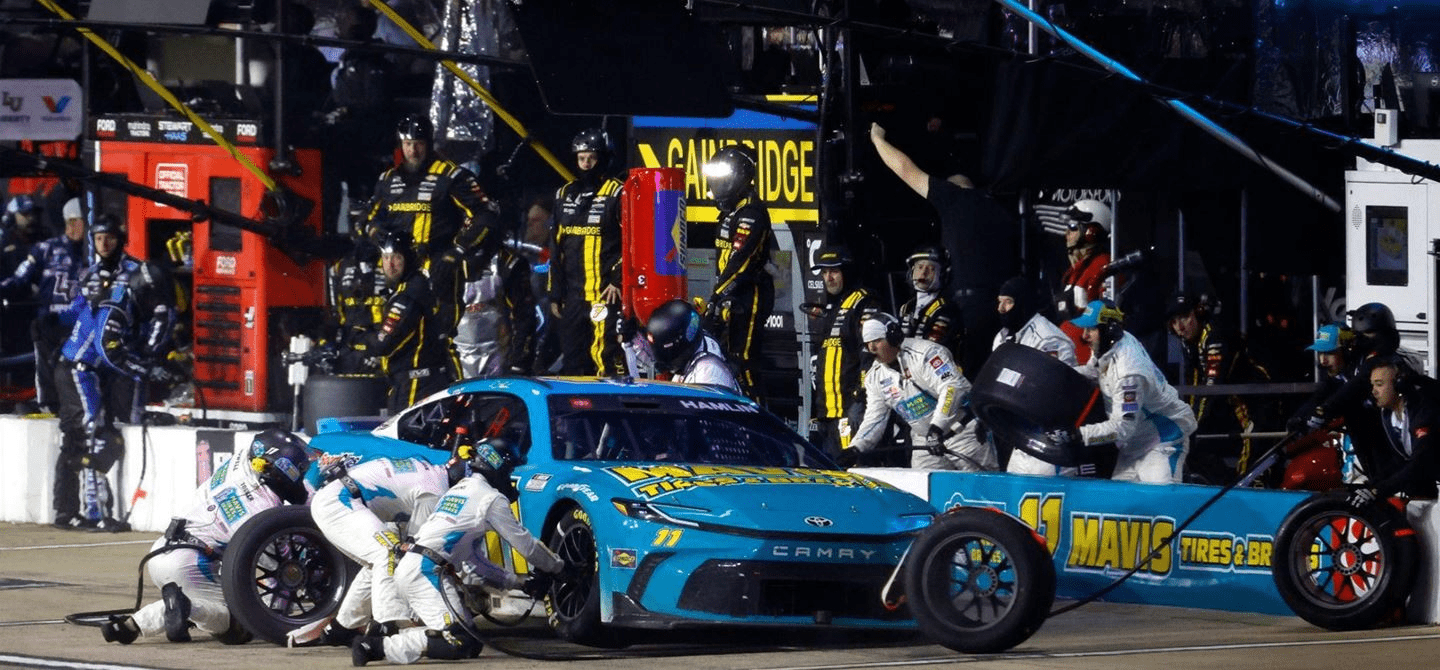

Denny Hamlin stops for fuel and tyres. JGHPI estimates that NASCAR pitstops are 10 times more impactful than F1 pitstops.

Joe Gibbs Racing is third in the all-time NASCAR Cup Series win tally behind Petty Enterprises and Hendrick Motorsports

/xpb_1300472_hires-(1).jpg?cx=0.52&cy=0.57)