Motor

How the F1 turbo engine evolved – from brutality to efficiency

by Steve Rendle

9min read

Formula 1’s regulations have been through various iterations since the birth of the world championship, but we had to wait until 1977 before the first turbocharged car would appear in F1.

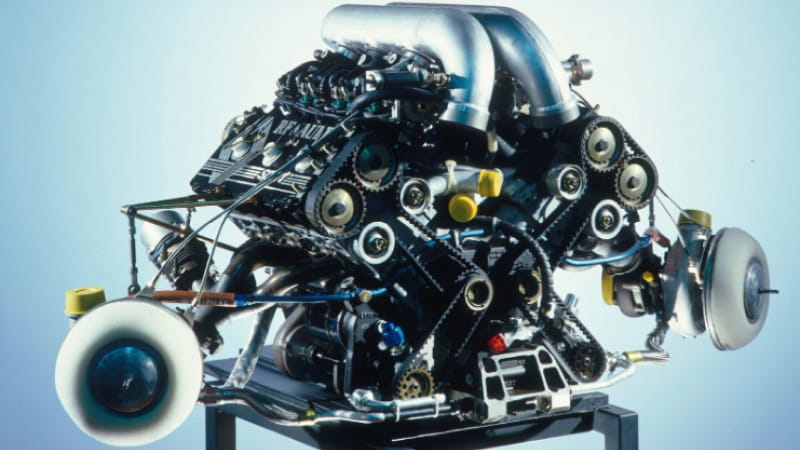

Renault, prompted by its success with a turbocharged sports car engine, took the bold decision to adapt its know-how to compete in F1.

The result was the Renault RS01, powered by a V6 single-turbo engine, debuting at the 1977 British Grand Prix. Initially, the engine was plagued by reliability problems due to the fragility of the turbo itself and the increased strain on the engine because of the higher pressures and temperatures associated with the use of turbos. It would be a year before the Renault finished a race, but two seasons after the engine’s debut, a now twin-turbo Renault won the French Grand Prix.

These early turbo engines suffered from significant turbo lag. Under overrun conditions, the turbos did not spin quickly enough to provide instant boost. So, until the engine revs rose there was insufficient exhaust energy to accelerate the turbines to provide the required boost pressure.

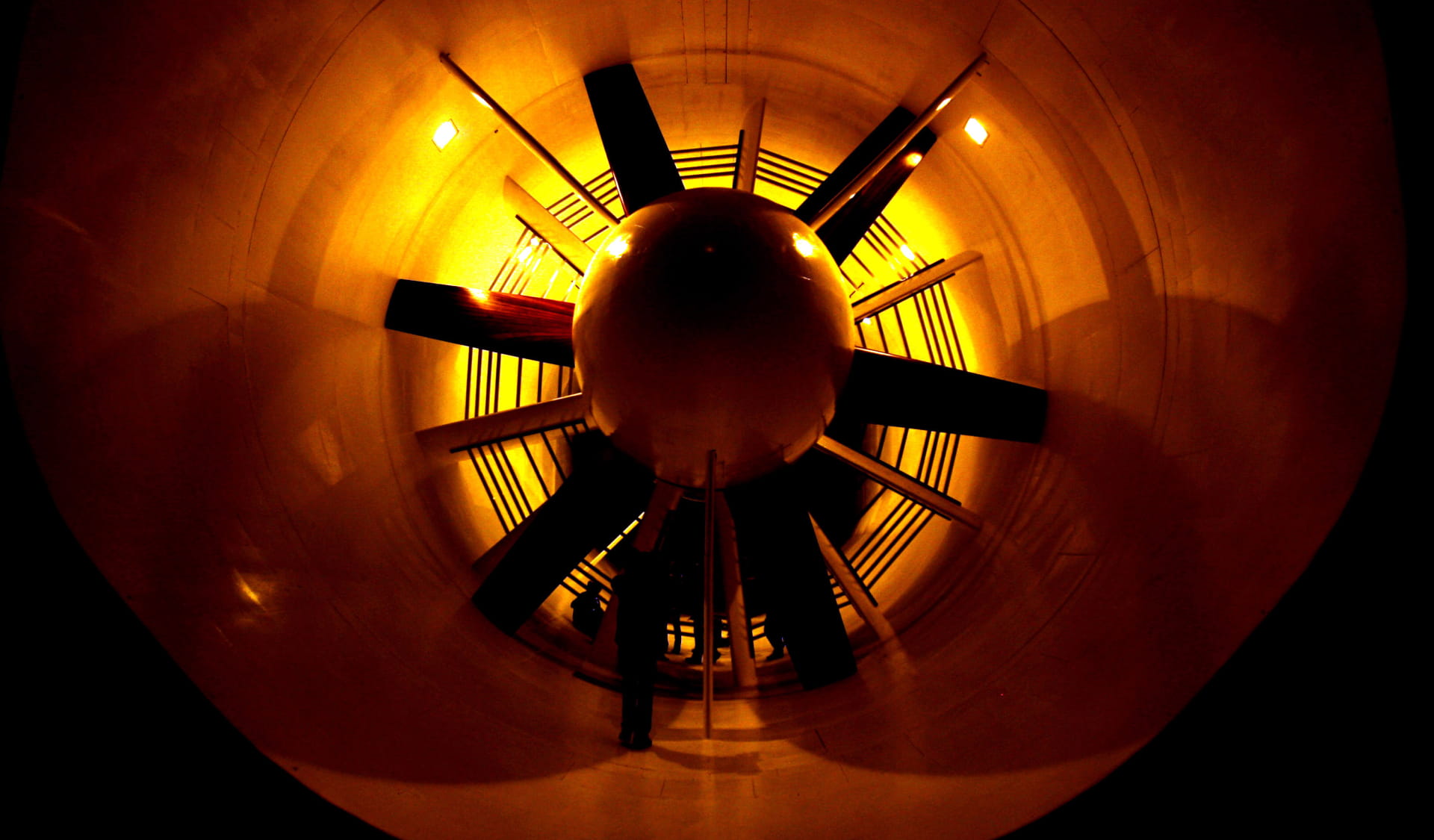

This resulted in poor throttle response in corners, with a rapid – often brutal – increase in power and acceleration on straights.

The twin-turbo Renault F1 engine suffered from turbo lag

With normally aspirated engines still comfortably holding their own against the Renaults, other teams were slow to adopt turbos. Ferrari was the first to follow suit in 1981, a season that saw the Ferraris and Renaults regularly retiring, often belching smoke and fire.

However, by the dawn of the 1983 season, it was becoming clear that turbo engines were the way forward, and Brabham-BMW and Toleman-Hart joined the turbo club. In 1983, 50% of the races were won by turbo cars, and the writing was on the wall for normally aspirated engines – Nelson Piquet taking the first World Championship for a turbo car with the Brabham-BMW BT52.

The turbo-engine development war

The BMW engine featured a Bosch electronic fuel-injection system, a major step forward in optimising combustion and varying ignition and fuel maps to unleash the full power potential of the engine, while improving reliability. With no restrictions on budget, boost levels, fuel, or the number of engines that could be used, the gloves were off and a turbo-engine war was about to break out.

The explosive BMW-powered Brabham-BT52

By 1984, all but one team had moved to turbos, and the engines were consistently producing 100bhp more than their normally aspirated counterparts in race trim, and closer to 200bhp more with special qualifying engines.

Fuel chemistry became a major factor in the quest for power, and special blends of ‘rocket fuel’ were produced to maximise the energy released and enhance engine cooling, leading to significant power gains. By 1985, some fuels were thought to contain 80% toluene, with 20% other constituents to ensure the legality of the fuel as ‘petrol’.

Turbo-engine development arguably peaked in 1986, and the BMW four-cylinder engine was reckoned to have run in qualifying trim using over 5bar boost to produce an estimated 1,300bhp. The results were spectacular – noisy, smelly and ferocious, with smoke trails of unburned hydrocarbons often seen in a car’s wake due to the rich mixtures and substantial valve overlaps used to control combustion and turbo temperatures.

The early turbo era was noisy, smelly, and ferocious

Turbocharger technology advanced rapidly, with the early turbine shaft plain bearings evolving to floating bearings, and even roller bearings. Intercooler efficiency was maximised, and for qualifying some teams devised total-loss water-spray systems directing water directly onto the intercooler cores, while engine-management systems became ever-more sophisticated.

Some teams used water-injection systems to increase the density of the mixture entering the combustion chambers, and turbine speeds increased from around 140,000rpm to 180,000rpm. Materials technology also advanced rapidly, with the development of sophisticated steels and ceramic components to withstand the high speeds, temperatures and forces within the turbos.

In a bid to curb escalating power and speeds, restrictions on fuel-tank capacity and boost levels were progressively introduced between 1985 and 1988, before turbos were outlawed for 1989, not reappearing in F1 until 2014.

The return of F1 turbos

So, how do the turbo engines used during the 1980s compare with the 1.6-litre V6 single-turbo hybrid units used since 2014?

Firstly, the current regulations are far more restrictive than those in the 1980s. Today, the Internal Combustion Engine (ICE) is used as part of an integrated ‘hybrid’ package with an Energy Recovery System (ERS).

Huge strides have been made in engine thermal efficiency, and whereas a 1980s turbo engine had a thermal efficiency of around 20–30%, the current F1 ICEs have a thermal efficiency of more than 50%.

continues below

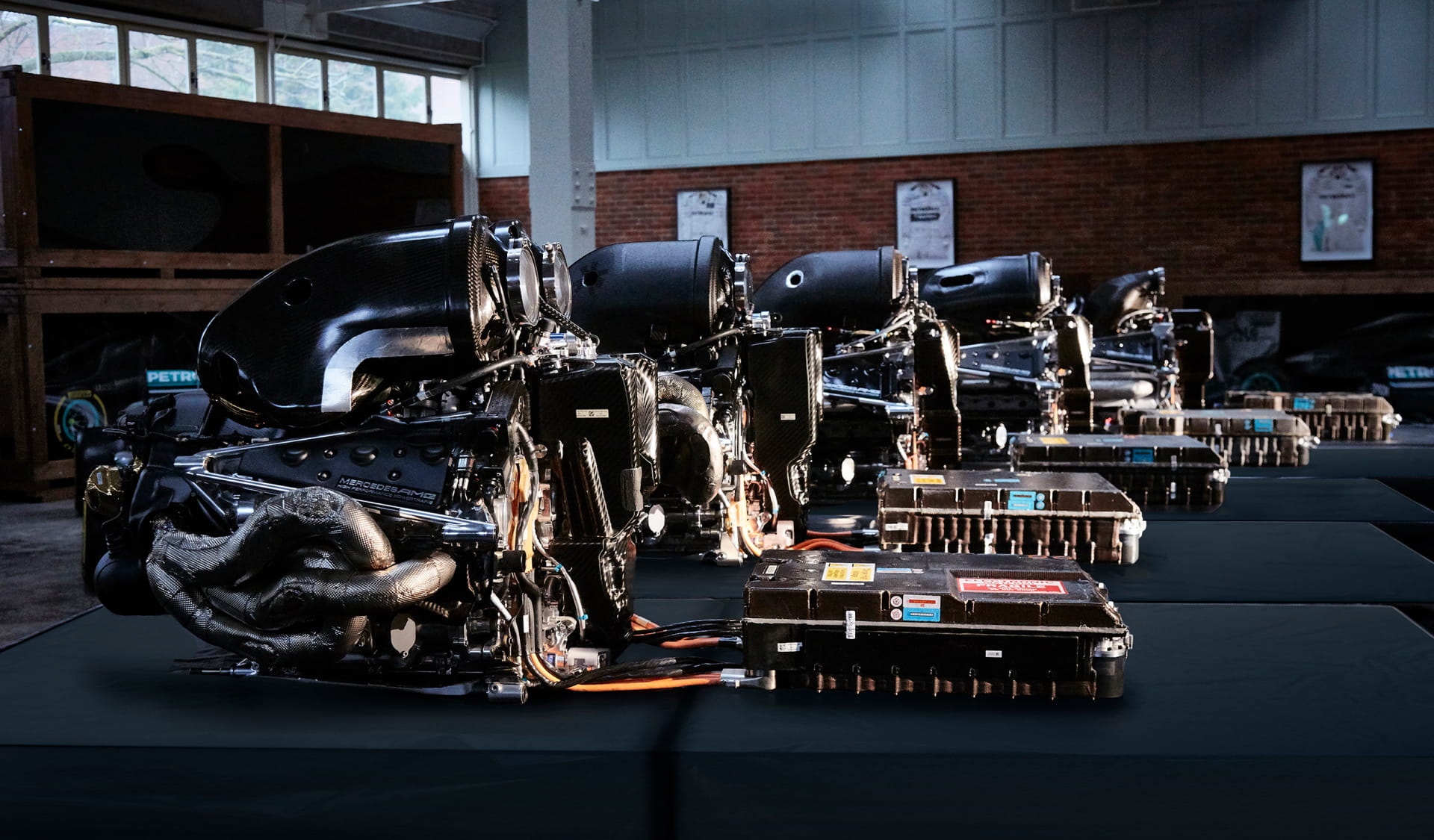

Today's Formula 1 V6 turbo-hybrid engines are efficient yet potent

Today’s engines use indirect fuel injection, with injection pressures of up to 500bar, and engine management systems have become far more complex, enabling much finer control of performance and improved reliability.

Hybrid power-unit turbo lag is minimal, as the MGU–H (Motor Generator Unit–Heat) element of the ERS can be used to control the speed of the turbocharger (currently restricted to 125,000 rpm), reducing its speed in a similar manner to a conventional wastegate, or increasing the speed to reduce turbo lag. Efficient use of the MGU–H can provide significant extra performance.

Another major innovation with today’s engines is the use of ‘split’ turbos, with the turbine split from the compressor – a configuration pioneered by Mercedes. With this system, the compressor is mounted at the front of the engine and the turbine at the rear, with the MGU–H positioned between the two elements, within the engine ‘vee’, and the three components connected by a shaft. This provides significant benefits for packaging and cooling.

Today, the maximum power produced by hybrid power units is similar to that produced in race trim at the peak of the first turbo era, but the designers’ aim is unchanged – to build a car to be as fast as possible within the regulations.

However, today’s cars provide a far more sophisticated solution, with more recognisable links to road cars and greater relevance to the challenges faced today by motor manufacturers, whilst still providing the ultimate motorsport excitement and spectacle that defines Formula 1.