Car

The evolution and construction of monocoque chassis in motorsport

by Steve Rendle

3min read

A monocoque chassis forms the backbone of most modern single-seater and sports competition cars. With a monocoque, the entire homogenous chassis structure is stressed, directly carrying all the loads applied to it.

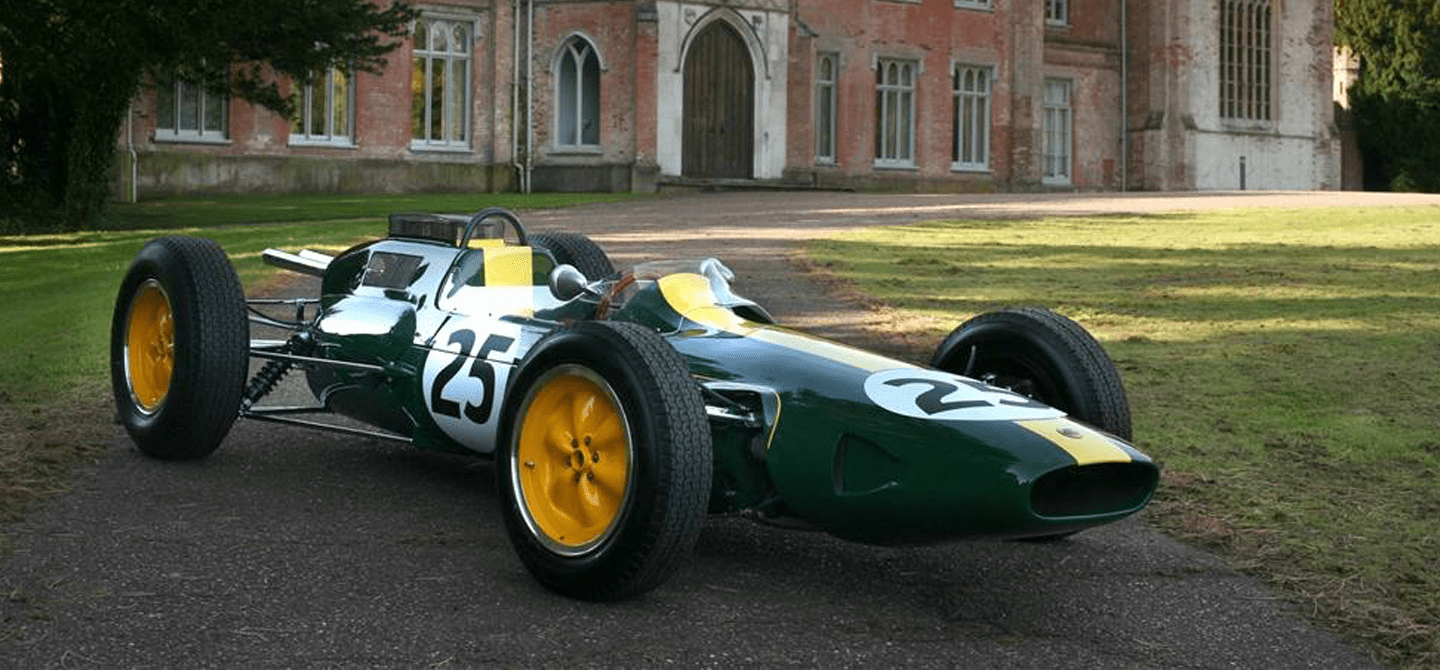

The Lotus 25 is the first Formula 1 car to use a monocoque chassis

The advantages and roots of monocoques in F1

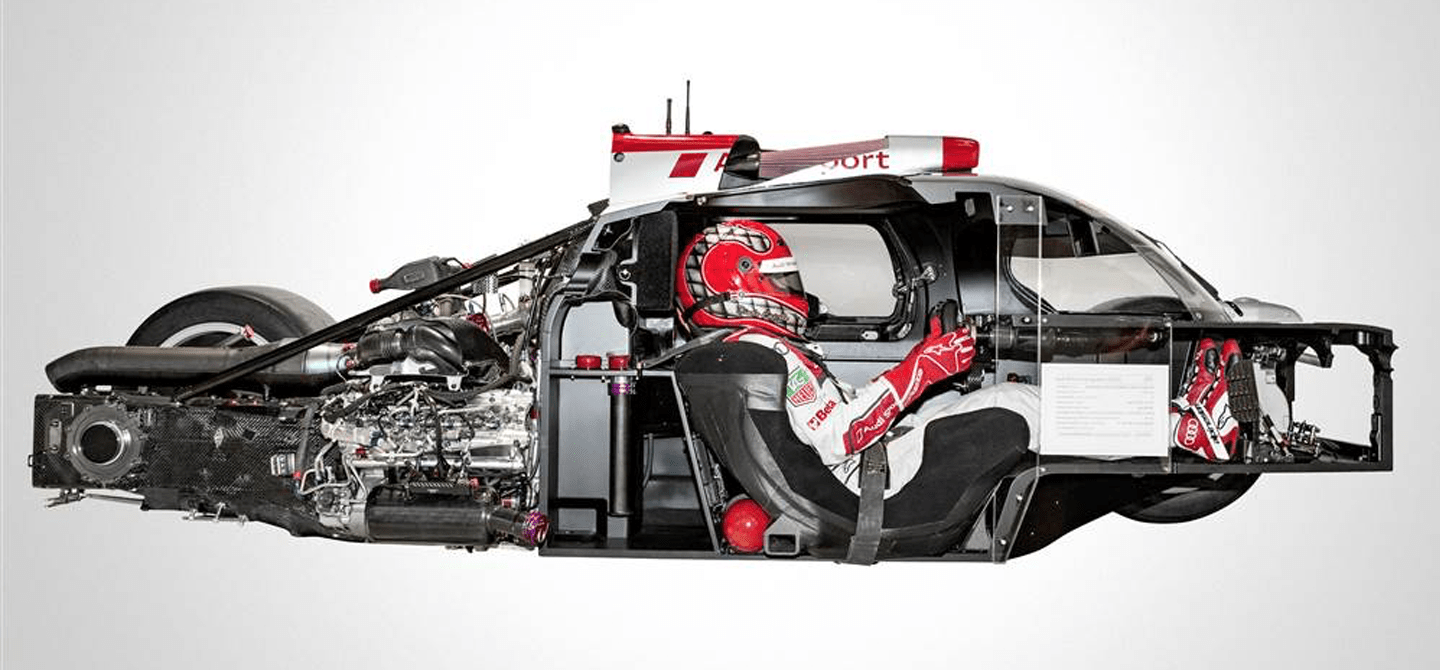

An example of a monocoque in another motorsport. The Audi R18 was campaigned by Audi in the LMP1 class of the World Endurance Championship until 2016. The engine is bolted directly to the monocoque here.

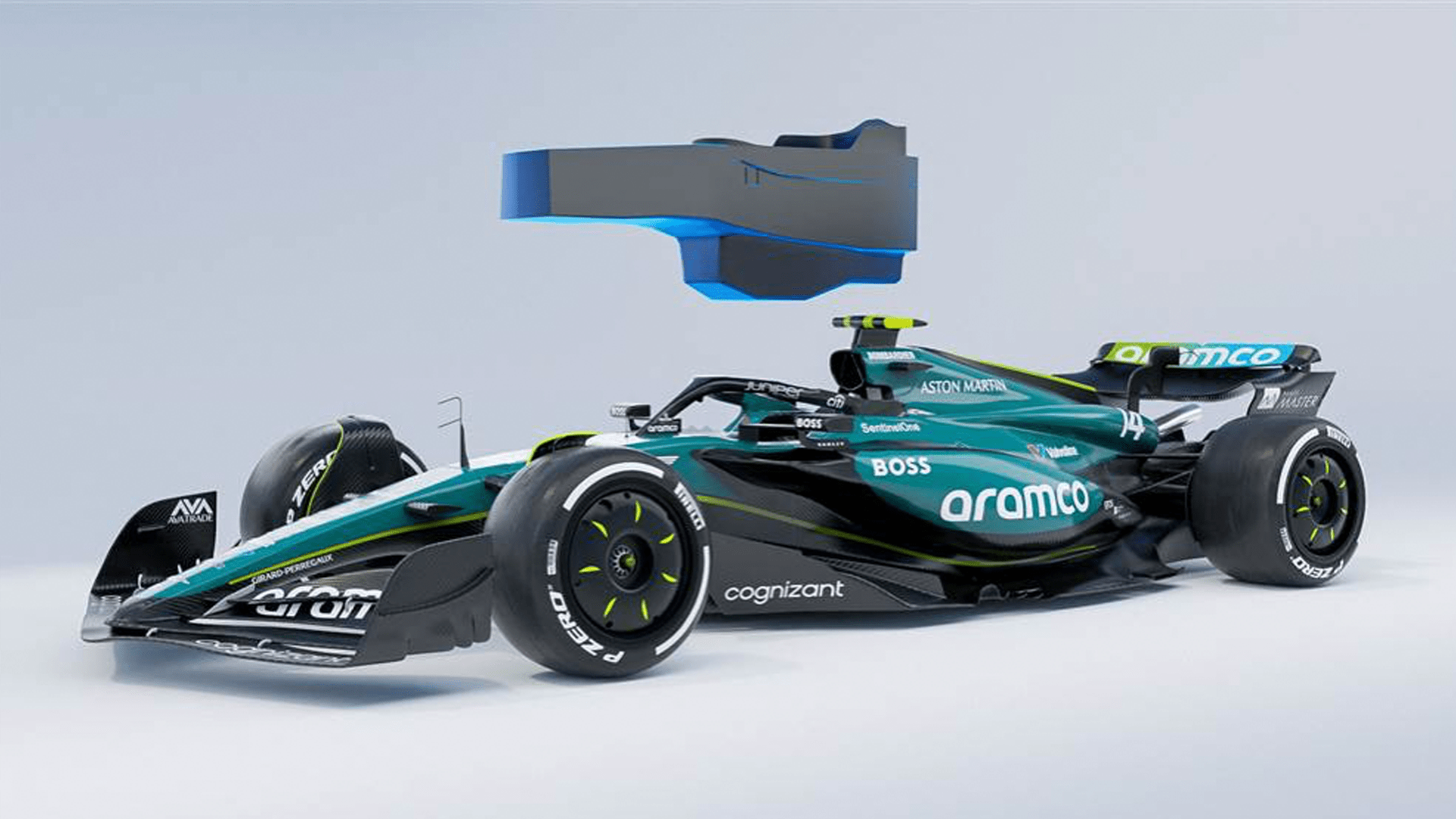

Computer Aided Design (CAD) is used in the production of an F1 chassis

How carbon monocoques are designed and produced

A close-up look at carbon-fibre, showing a ‘weave’ pattern following a certain calculated direction for rigidity

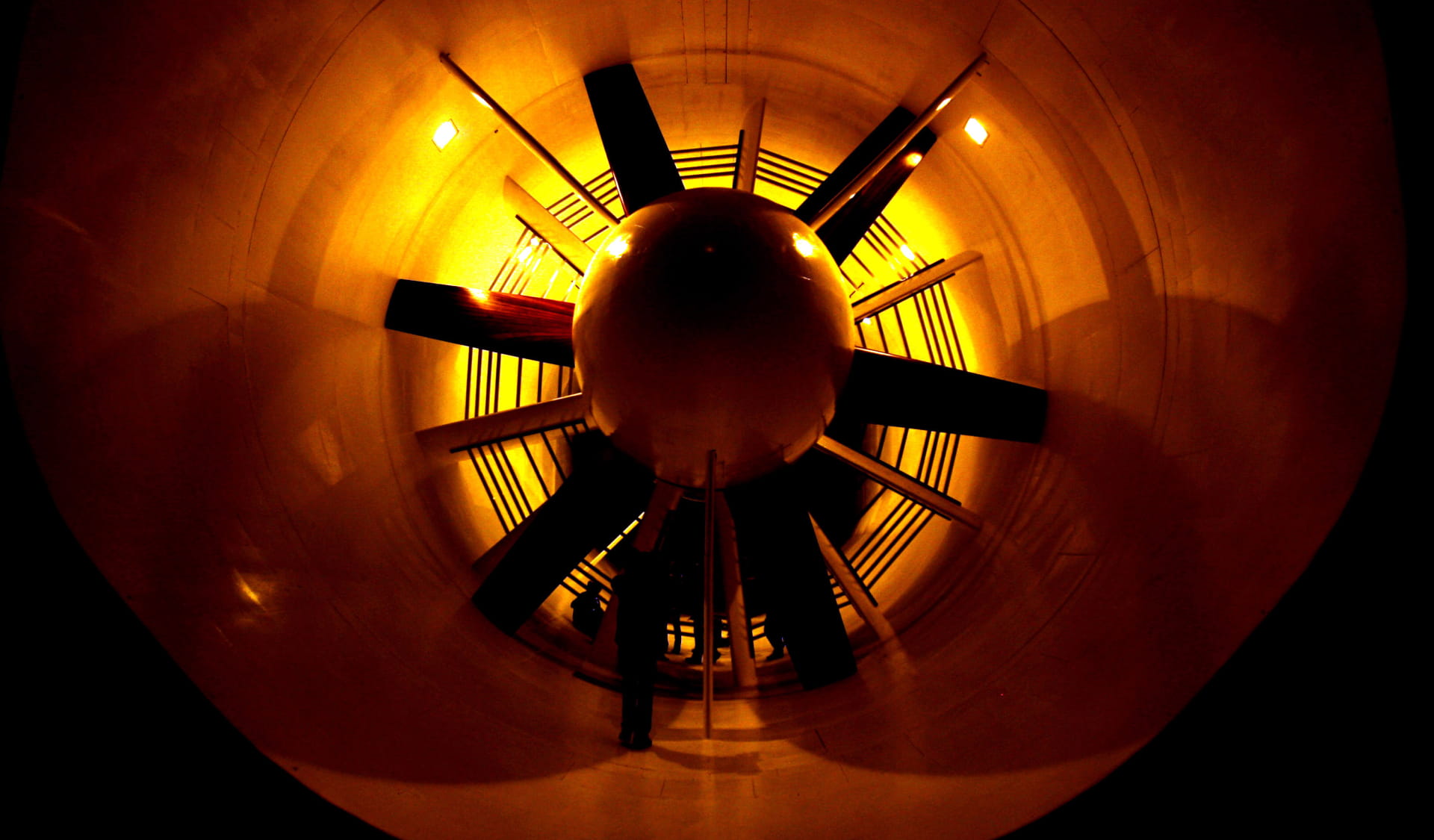

Inside an autoclave - an ‘oven’ that bonds together layers of carbon fibre

The completed monocoque is machined and trimmed to provide any final detailing, along with mounting points for suspension and other components.

In many cases, a sample monocoque must be subjected to a set of homologation tests. These are primarily structural tests to ensure the structural integrity of the survival cell in the event of a serious accident.

Finally, the finished monocoque normally undergoes a rigorous inspection and Non-Destructive Testing (NDT) process, prior to being released for use as the basis of a car.

The end result is a solid, lightweight carbon-fibre monocoque that forms the central part of the F1 car - protecting the driver and providing the foundation to add performance-enhancing aerodynamic components.

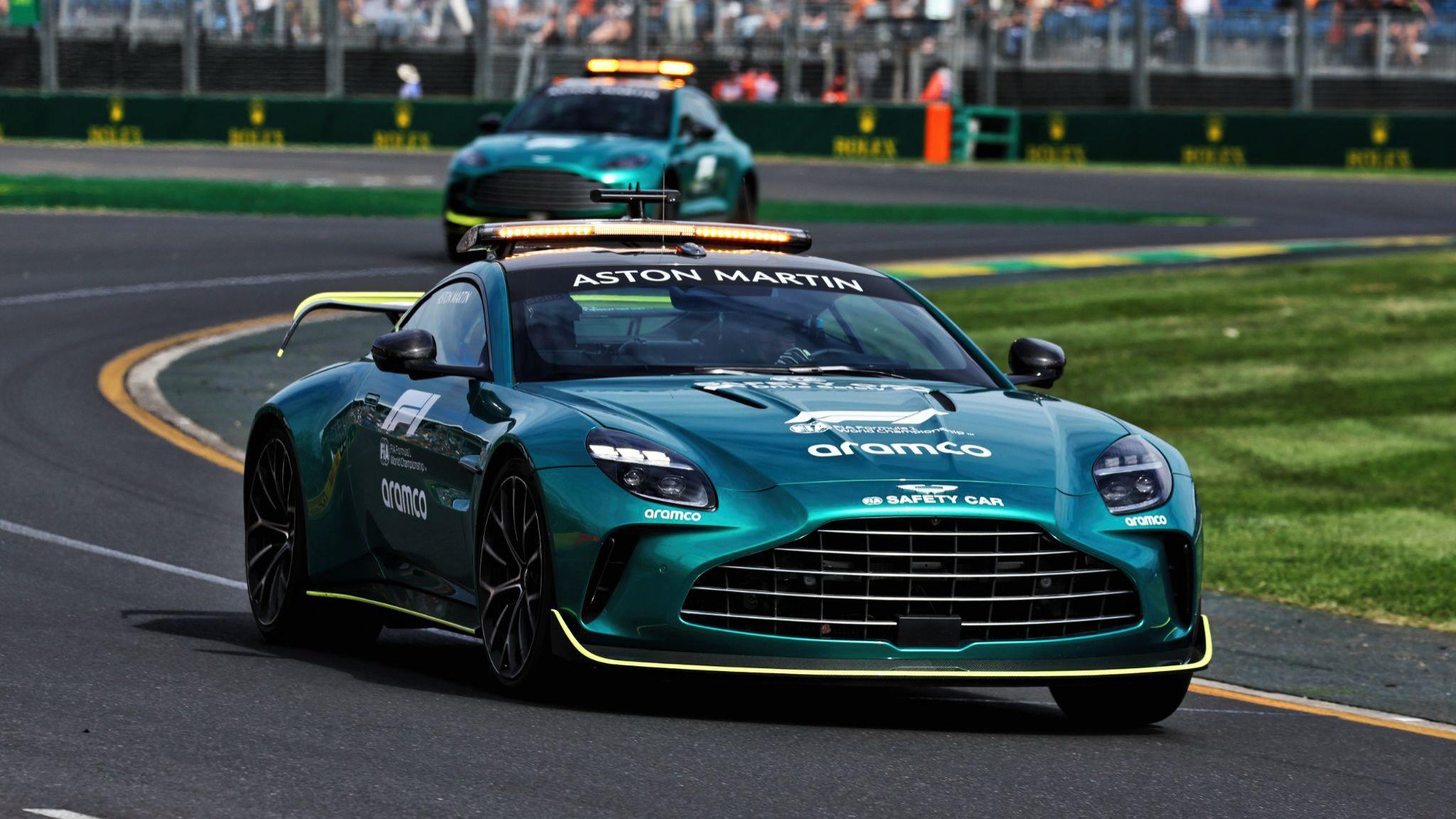

/xpb_1300472_hires-(1).jpg?cx=0.52&cy=0.57)