Car

The science behind tyre degradation in Formula 1

by Gemma Hatton

4min read

When you watch a motorsport race, it’s not long before someone starts talking about tyres. Are the tyres degrading? How long will they last? What is the working range?

Innovation, Car

F1 safety: How Formula 1 drivers are protected from accidents

So, what actually is tyre degradation and why do tyres degrade in the first place? In this article we uncover the fundamentals of how tyres generate grip, as well as the different mechanisms of tyre degradation.

How do tyres work?

How does a tyre generate grip?

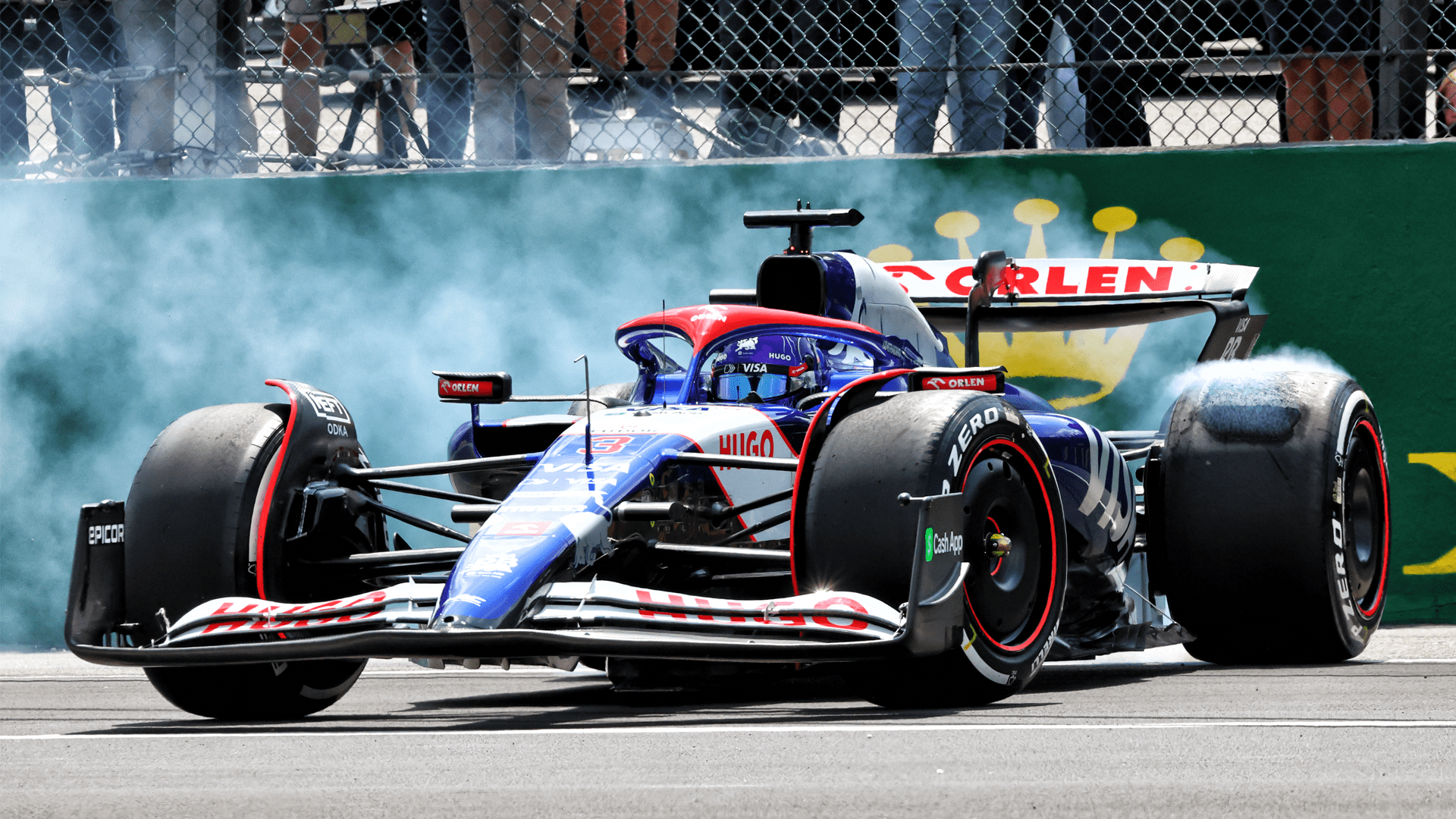

A lock up under braking drags the tyre across the track, wearing through a patch of the rubber

What is the working range?

Both hard and soft compounds can be designed to work at any working range. In Formula 1, Pirelli match soft compounds with lower working range temperatures and hard compounds with high working range temperatures.

Softer compounds are more flexible and so the rubber stretches and compresses more which generates heat. This ability to warm up faster enables soft compounds to produce grip more easily, making them more suited to a low temperature working range. Otherwise, the heat generated by a soft compound combined with a high temperature working range would cause the rubber to overheat and degrade.

Harder compounds on the other hand are much stiffer and therefore generate minimal heat on their own. Instead, they rely on high-speed corners and rough track surfaces to excite the rubber. This can lead to much higher temperatures in the rubber and therefore are more suited to a working range at high temperature.

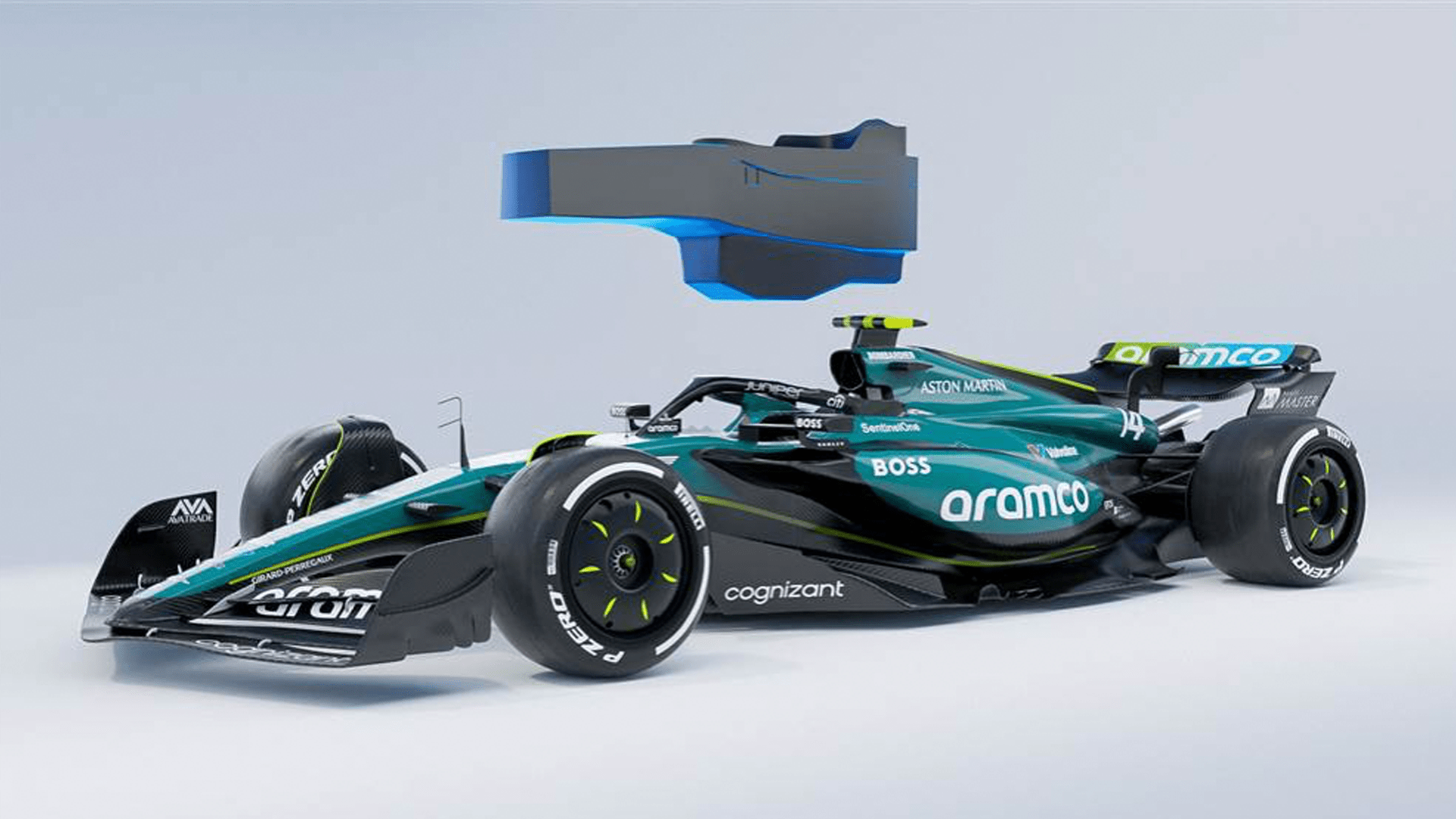

"Soft compounds are easier to warm up and to reach their optimum temperature, so are better suited to cool conditions and smooth tracks with less high-speed corners, where it is typically difficult to get enough energy into the tyres,” highlights Eric Blandin, deputy technical director at Aston Martin Aramco F1 Team. “Whereas hard compounds are more robust and so can generate grip at tracks with high surface temperatures and roughness, without overheating or damaging the surface of the tyre.”

.jpg?cx=0.5&cy=0.5)

Pirelli nominate one of the five compounds to be the Hard, Medium or Soft for each race. Graphic courtesy of Pirelli.

What is tyre degradation?

When a tyre does not have enough grip, it slides across the surface of the road. This sliding effect generates temperature which overheats the rubber, causing two types of degradation:

- Thermal degradation

- Wear degradation

Thermal degradation is where the rubber is so hot that its material properties change, and the compound becomes much harder. This means it cannot stick to the surface of the track as much, leading to a smaller contact patch and much less grip.

Wear degradation is where the rubber slides across the track, causing pieces of rubber to wear away, resulting in surface damage. With less rubber in contact with the track, less grip is generated.

There are several mechanisms of wear degradation that we see in Formula 1:

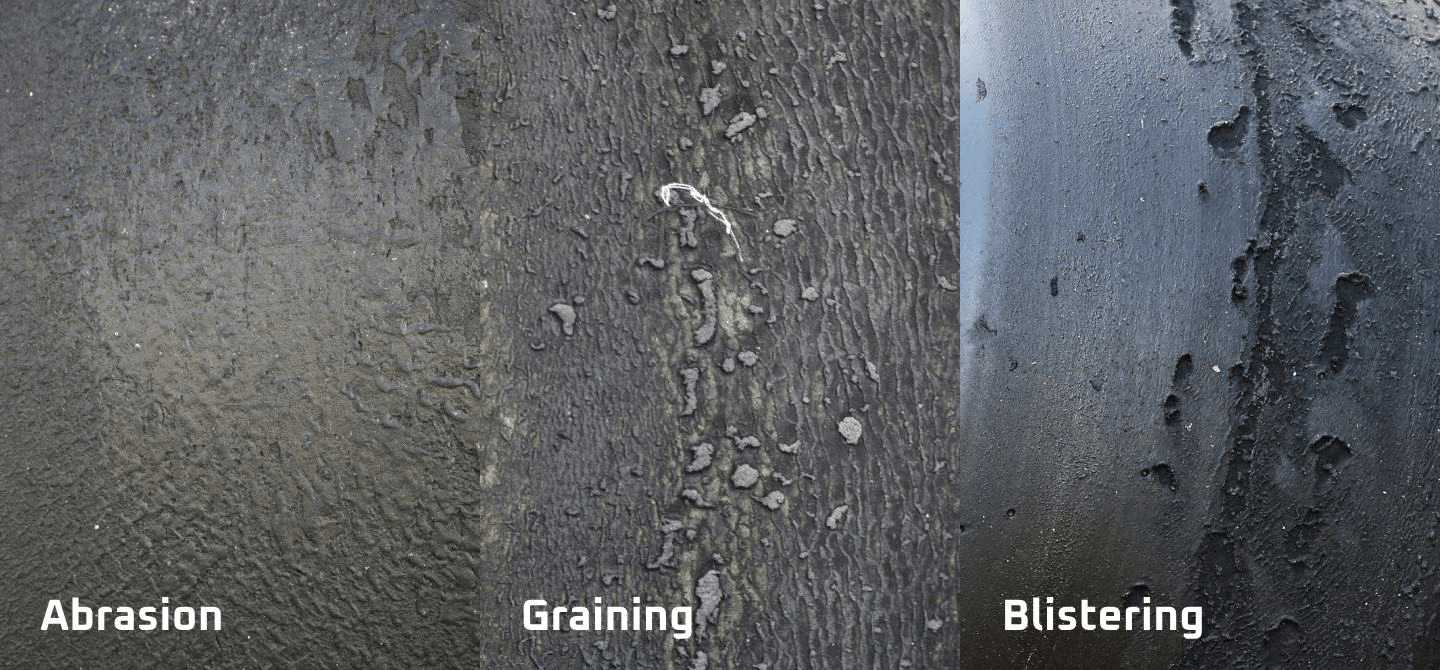

Abrasion: As the tyre slides across the track, small portions of rubber are worn away from the surface, leaving a uniform pattern of ridges and spots. This is often referred to as ‘normal’ wear.

Graining: A more extreme version of abrasion, where rubber shears away from the surface and rolls into small grains, similar to dragging an eraser across paper. This leaves a pattern of wavy ridges on the surface which from a distance, appears as a dark band on the tyre.

Blistering: The rubber overheats and essentially boils, producing bubbles that then explode, removing chunks of rubber from the surface. This is rare with the current Formula 1 compounds, but can sometimes be seen in the centre or on the outer edges of a tyre.

Abrasion, graining and blistering are the main forms of tyre degradation we see in Formula 1

Why do race tyres degrade more than road tyres?

For a racecar to achieve fast lap times, its tyres need to generate an extreme amount of grip so that it can accelerate, brake and corner quickly. Therefore, the tyre compounds used in motorsport are much softer than the compounds used in road tyres.

Soft compounds warm up faster, increasing the ‘stickiness’ of the rubber which maximises the contact patch area, leading to higher grip. However, the punishing longitudinal and lateral loads, combined with the constant sliding that race tyres are subjected to, leads to accelerated wear and degradation.

Road cars travel at slower speeds and consequently demand much less grip from the tyres. This means that road tyres can be made from harder compounds that operate at cooler temperatures and don’t wear as much. In fact, a typical road car tyre can last up to 40,000 miles (64,000 km) whereas the longest stint on a Formula 1 tyre last season was 188 miles (302.5 km).

How has Pirelli improved tyre degradation?

The introduction of the 18-inch wheels and larger tyres in 2022 provided an opportunity for Pirelli to develop a new range of compounds that avoided the overheating issues seen in previous seasons. "To reach this target we needed compounds that had a much wider working range, especially at higher temperatures,” says Berra. “We worked with our materials department to deliver compounds with these characteristics and we are now seeing fewer comments about this overheating effect."

“Graining and wear are still evident but that’s part of the game in Formula 1 because we are stressing the compounds to their mechanical limits,” continues Berra. “However, we have still tried to improve this by designing the new compounds to have more uniform wear. This avoids wearing just a portion of the tyre and instead wears the tyre evenly, helping to make the tyres last longer.”

As impressive as this is, from an entertainment perspective we actually don’t want tyres that last too many laps because this will remove the need for pitstops which are an exciting element of Formula 1 races.

Consequently, Pirelli have to tread a fine line between developing tyres that deliver maximum performance for the teams, whilst meeting the FIA’s desire for pitstops.

/xpb_1300472_hires-(1).jpg?cx=0.52&cy=0.57)