Event

Formula 1: The data behind 2025 pre-season F1 testing in Bahrain

by Jack Chilvers

6min read

.jpg?cx=0.5&cy=0.5)

The official 2025 Formula 1 Aramco pre-season test gives us the first chance to see the new grid of F1 cars take to Bahrain International Circuit on February 26-28.

Sign up for a weekly newsletter and we'll make sure you're fully up-to-date in the world of race technology

Over three days of testing, teams will assess the performances of their respective cars and drivers and decide how best to proceed before the first race of the season in Australia on March 16.

Of course, the work has already begun; F1 teams have been busy over the winter break - firing up their engines, drawing up run plans for the pre-season test and ensuring everything goes smoothly when the lights go green in Bahrain at the end of February.

Aerodynamicist Jack Chilvers looks into what the teams’ respective aerodynamics departments have done in the build-up to F1 pre-season testing, the data that is gathered during the test itself, and what they can glean from the three days of running in Bahrain.

Lewis Hamilton testing for Ferrari at Fiorano, Italy. Pre-season testing will give us the first chance to see drivers like Hamilton perform for their new teams in the 2025 F1 cars

Preparing for the test

Within each F1 team, a team of aerodynamicists are hard at work all year exploring new concepts and iterating existing ones with the sole aim of finding every tenth - or even thousandth - of a second of laptime improvement.

With this being the last year using the current regulations, it’s likely that many concepts will be a refinement of those run previously (although we may see some rolls of the dice come Bahrain).

Through this development, a launch car geometry will be defined in advance and handed over to the design office for the first test with potential test items following shortly thereafter.

With the launch geometry defined, the aerodynamic performance group - the bridge between aerodynamic development and on-track performance - will embark on a huge data-gathering exercise, using both computational fluid dynamics (CFD) and windtunnel methodologies to better understand the aerodynamic behaviour of the racecar.

This body of data is fed into a driver-in-the-loop simulator to gather yet more data on how the car is performing and to gain valuable insight into the optimum set up for a given track. After the fact, the track data can then be used to complete the loop on how well the simulation tools are correlating with the real-world environment.

The simulator at Mercedes F1 Team’s Brackley, UK, headquarters

The first laps in Bahrain

Despite all of the preparation and planning that goes into the first test, it is a nervous time for those both trackside and back at the factories. Whilst the car will have undoubtedly improved according to all of the development metrics used by the team, there’s no guarantee that it will have been enough to keep up with - or better yet, exceed - the pace of the competition.

The first pre-season test offers some of the first glimpses into this. There’s also the matter of whether the development tools have steered the engineers and aerodynamicists in the right direction.

During the first shakedown laps of the car, a lot of emphasis is placed on ensuring that all systems are operating as expected. Data from pressure tappings predominantly covering the wings and underfloor will be checked by the aerodynamicists to ensure they are responding as expected. Parameters such as brake and engine temperatures will also provide some level of confidence that cooling airflow is behaving well.

Once the car has been thoroughly shaken down, it’s time to begin to understand more about its strengths and weaknesses. As part of this, the driver may be asked to take different racing lines to cover more of the aerodynamic map with changes in onset yaw angle and car positioning (pitch, roll and steer).

Constant velocity cruises down the straights may also form part of the aerodynamic run plan in an attempt to gather quasi-static straightline data.

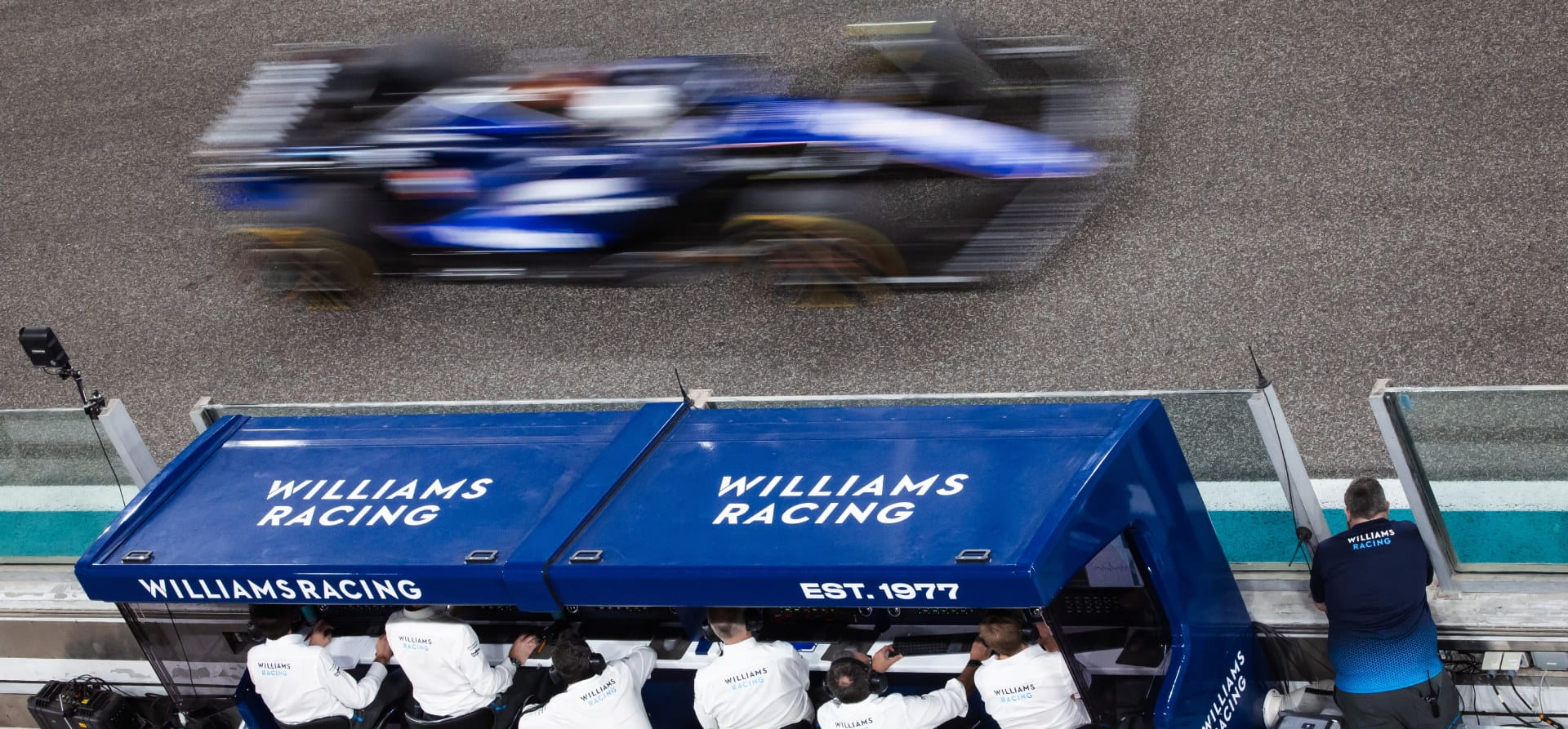

Williams F1 Team’s engineers examine the data as new signing Carlos Sainz passes by in the 2024 end-of-season F1 test

Aero rakes and flow-vis paint

Whilst the heading might conjure up images of the contents of a garden shed, aerodynamic rakes and flow-vis paint are just two of the tools used to better understand the flow behaviour across the race car during testing.

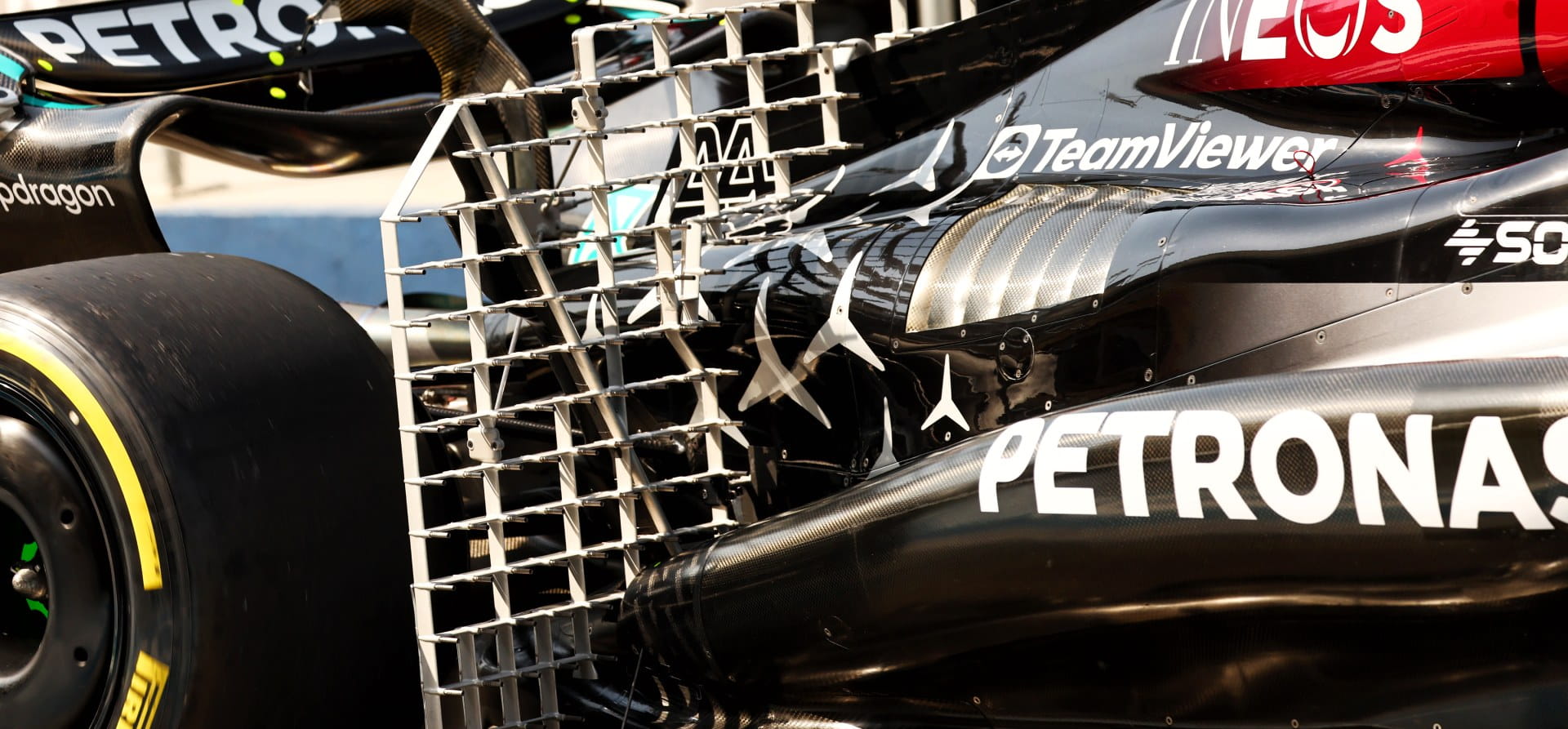

Rakes feature an array of pitot tubes which are capable of measuring the total pressure in the airflow close to the body of the car. In practical terms, this allows aerodynamicists to visualise flow structures such as wheel wakes and vortices.

Lewis Hamilton’s Mercedes F1 car fitted with an aero rake during 2024 pre-season testing

Data is gathered during the entire run, thus showing how the flow features develop and interact across a variety of conditions across the lap. It’s worth noting that rakes add blockage into the flow and, as such, will influence the results observed. For this reason, a significant amount of time is taken to optimise and align rake structures to the prevailing flow field.

Flow-vis paint usually consists of an ultraviolet-dye suspended in a low viscosity fluid which is painted directly onto the surfaces of interest across the car. This typically includes surfaces such as the underside of wings and the underfloor where flow tends to be worked harder. Whilst low tech and easy to apply, flow-vis will dry quickly and only provide an overall snapshot of how the surface flow is behaving.

For this reason, it is more useful for highlighting areas of sustained instability. It is also an arduous task to clean off and it will find its way through any cracks or crevices in bodywork.

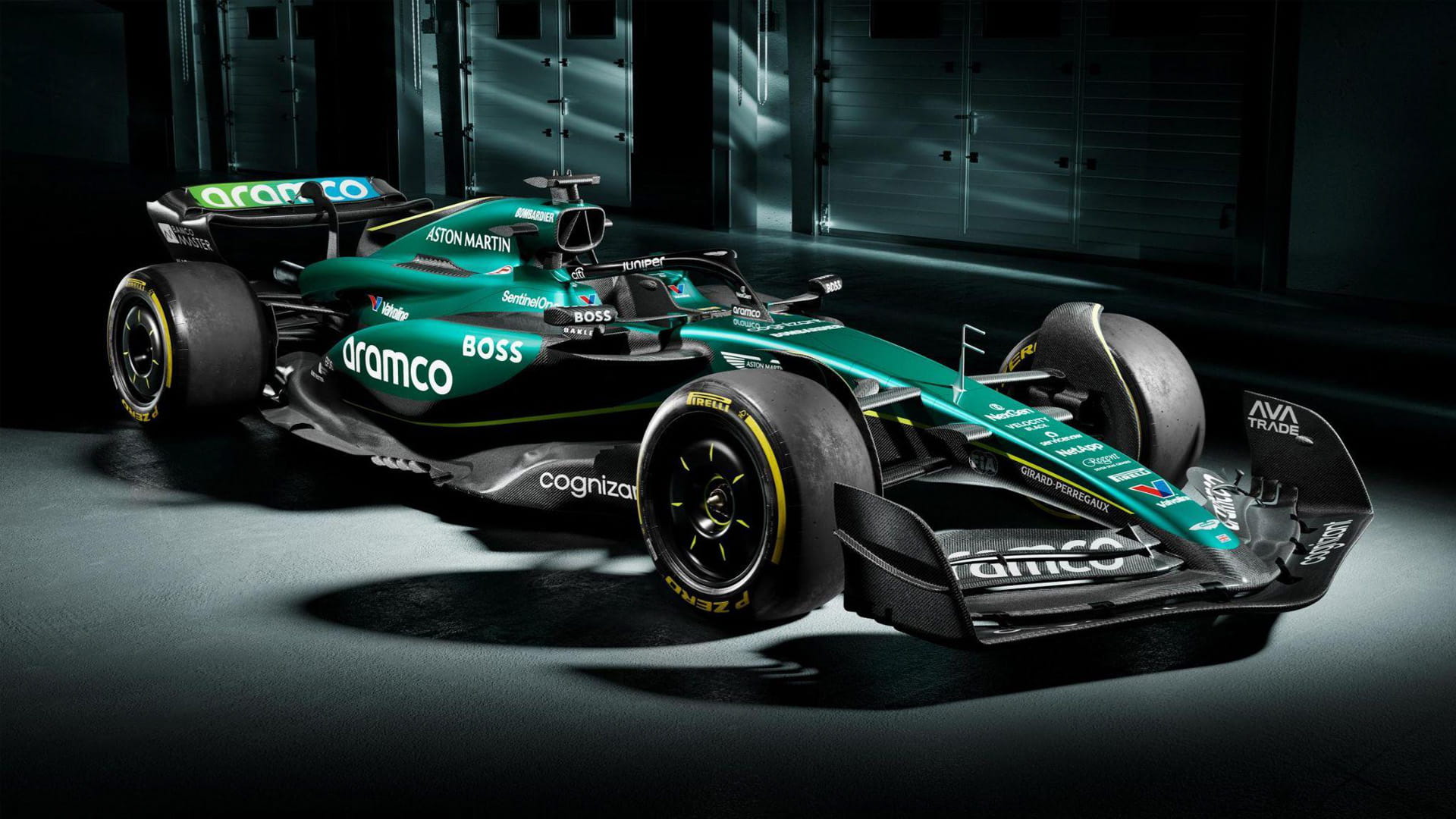

Lance Stroll’s Aston Martin Aramco F1 Team car covered in flow-vis paint during 2024 F1 pre-season testing

What to expect from 2025 pre-season F1 testing

As mentioned previously, 2025 is the swansong of the current technical regulations.

Whilst it isn’t unheard of for teams to throw the dice on a new concept late in the game, we might reasonably expect the next cohort of cars to have evolved from their predecessors as aerodynamicists gain confidence in the understanding of their designs.

Teams will no doubt be eager to get the edge on their competitors in 2026 now the flood gates have been opened which likely means more resources dedicated towards that goal (not forgetting the current cost cap and its implications).

Of course, there’s always the likelihood of certain teams developing their 2025 F1 cars even more if they sniff a chance of better results in the final era of these technical regulations - which could mean a better constructors’ championship standing and more prize money as a result.

After all of the testing is complete, it is then time to start sifting through the vast amount of data collected across each session. The first challenge is to filter through all of the noise in the data gathered on track; gusts of wind, traffic and tyre degradation all influence the aerodynamic state of the car amongst so many other factors. Teams will often make use of their own in-house codes to navigate their way through this task.

Making meaningful visualisations using post-processing techniques is another critical task undertaken by the aerodynamic performance group.

Turning pressure tapping and rake data into contour plots helps gain understanding into how the car is responding to changes in air flow and why this is happening.

Finally, this data and any conclusions drawn are shared with the rest of the aerodynamics department. This will then be used to investigate any areas of miscorrelation within the simulation tools. It will also better inform the next development steps to be taken with the continued goal of improving lap times.

Sauber F1 engineers pore through the data in Bahrain, 2024

Understanding testing data

After all of the testing is complete, it is then time to start sifting through the vast amount of data collected across each session. The first challenge is to filter through all of the noise in the data gathered on track; gusts of wind, traffic and tyre degradation all influence the aerodynamic state of the car amongst so many other factors. Teams will often make use of their own in-house codes to navigate their way through this task.

Making meaningful visualisations using post-processing techniques is another critical task undertaken by the aerodynamic performance group.

Turning pressure tapping and rake data into contour plots helps gain understanding into how the car is responding to changes in air flow and why this is happening.

Finally, this data and any conclusions drawn are shared with the rest of the aerodynamics department. This will then be used to investigate any areas of miscorrelation within the simulation tools. It will also better inform the next development steps to be taken with the continued goal of improving lap times.

.png?cx=0.5&cy=0.5)

.png?cx=0.5&cy=0.5)

.jpg?cx=0.5&cy=0.5)