Car

How Mercedes F1 helped Mercedes-Benz achieve a solid-state battery milestone

by Samarth Kanal

8min read

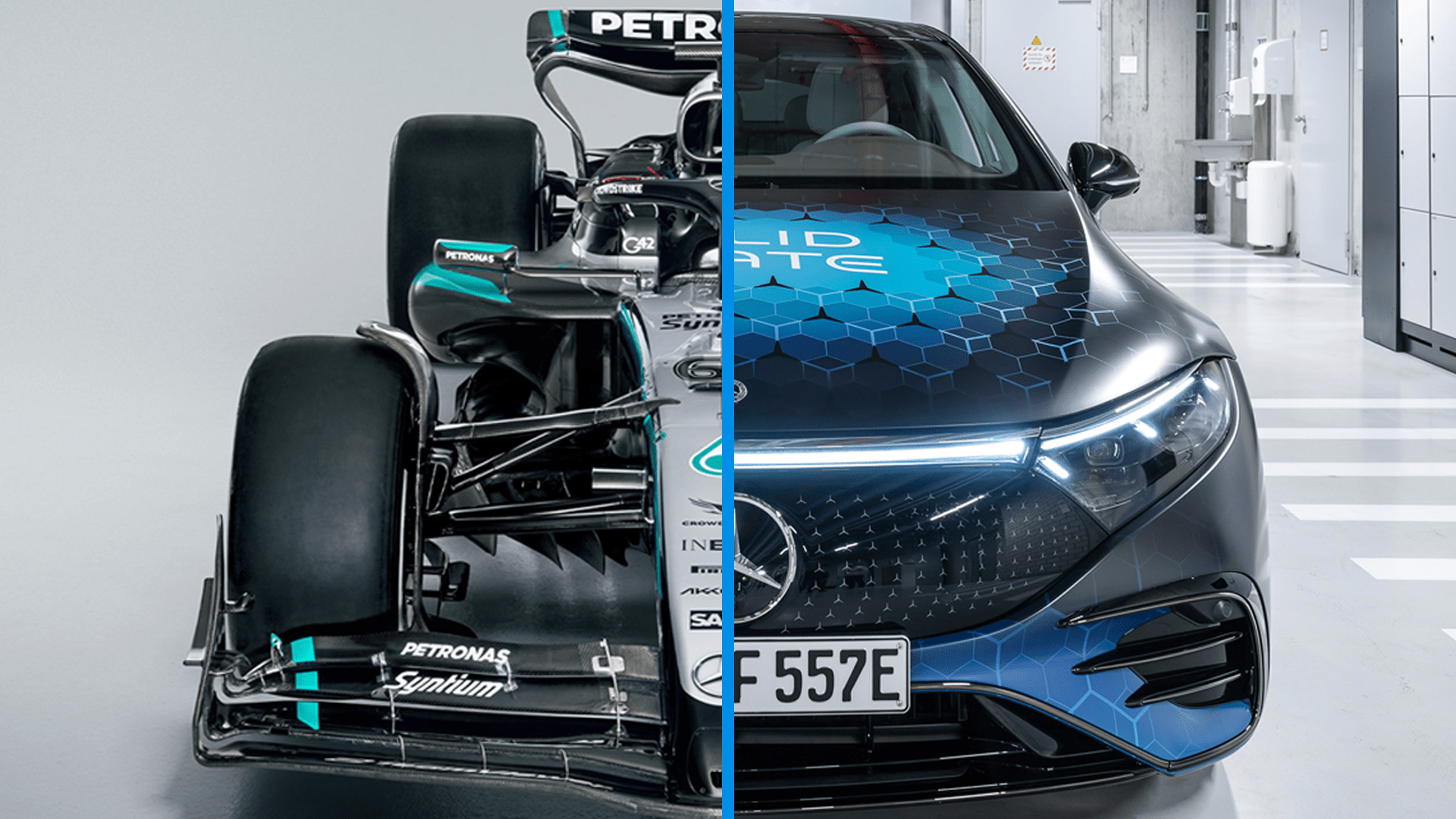

Mercedes’ road car company and Formula 1 engine builder Mercedes-AMG High Performance Powertrains (HPP) have teamed up to deliver the first lithium-metal solid-state battery to the road in the Mercedes EQS.

Sign up for a weekly newsletter and we'll make sure you're fully up-to-date in the world of race technology

What are solid-state batteries?

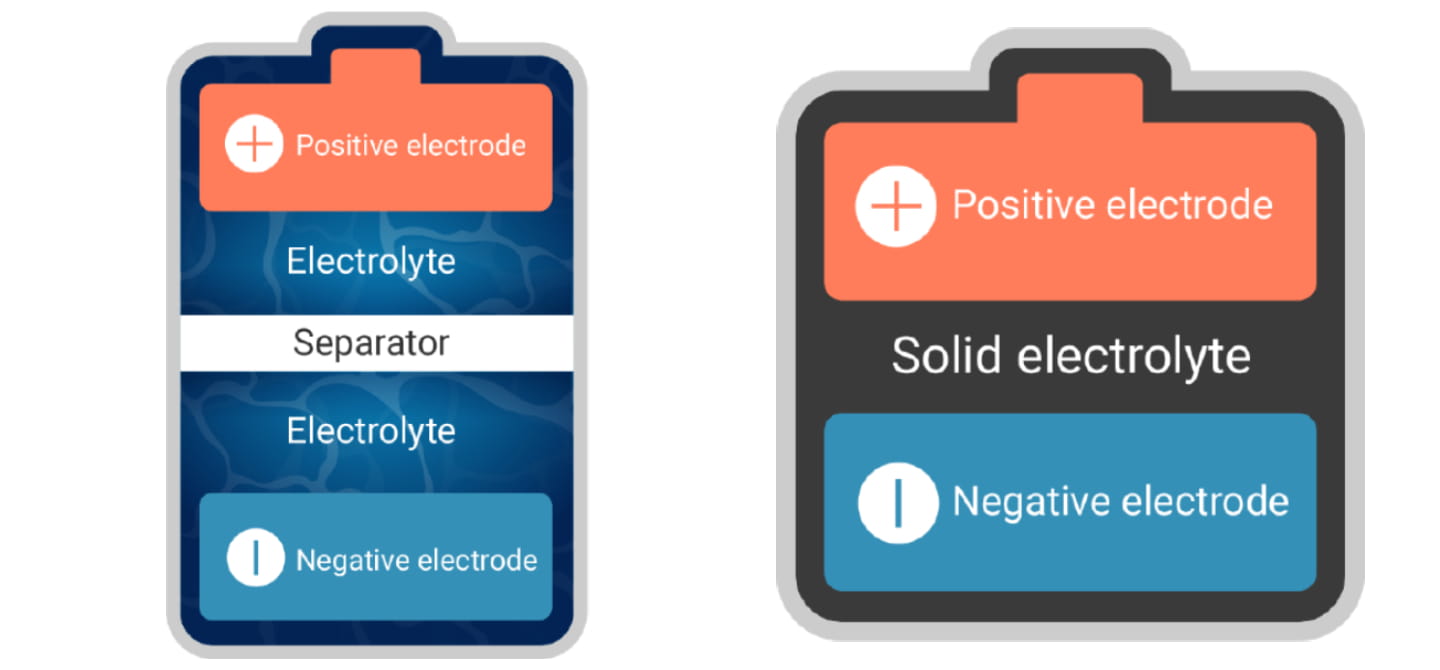

A comparison of a liquid electrode battery (L) versus a solid-state battery, courtesy of Honda

Lithium-ion batteries with a liquid electrolyte are also sensitive to temperature changes, which can affect the range of electric cars.

Solid electrolytes are more chemically stable and there is no risk of leakage, which means they are safer. Furthermore, they are far less sensitive to temperature changes. A solid electrolyte is also denser than a liquid, which means they can offer more potential energy in a smaller package and much quicker charging times.

Mercedes says its solid-state-powered EQS increases range by up to 25% compared to the existing EQS. It has a range of more than 1,000 kilometres or 620 miles for the solid-state vehicle compared to the existing EQS's range of 800km or 497 miles.

The solid-state battery-powered Mercedes EQS

The ‘breathing’ battery

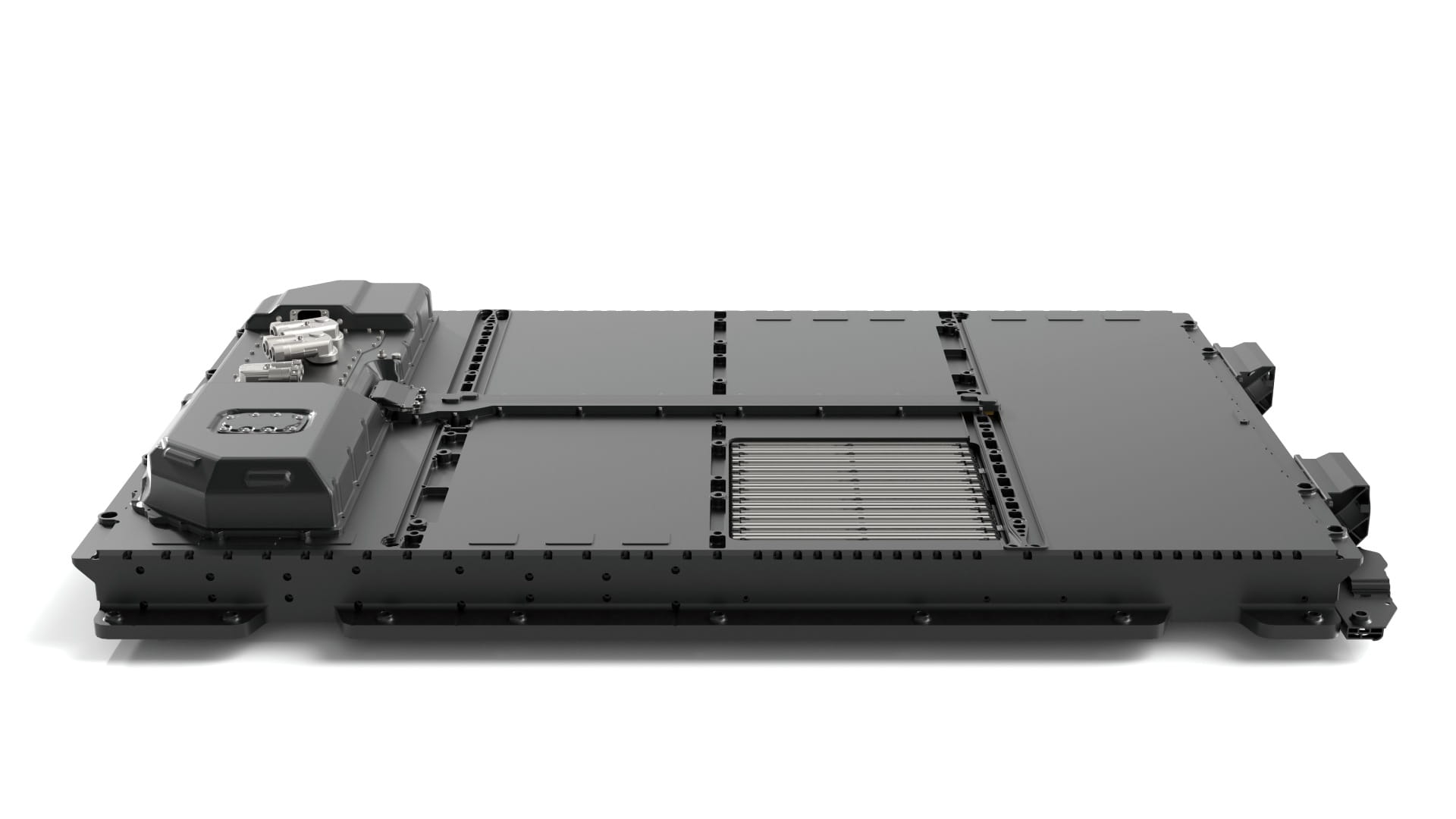

The solid-state battery used in Mercedes’s prototype EQS

Why has Mercedes enlisted help from its F1 engine builder?

.jpg?cx=0.5&cy=0.5)

Mercedes’s hybrid F1 power units lined up

The Mercedes AMG One hypercar at the Nurburgring, where it set a lap record in September 2024

Will solid-state batteries make their way into F1?

.jpg?cx=0.5&cy=0.5)

Our render of what the 2026 Formula 1 car could look like inside a windtunnel

/xpb_1314694_hires.jpg?cx=0.48&cy=0.64)

.jpg?cx=0.5&cy=0.5)

.jpg?cx=0.5&cy=0.5)

.jpg?cx=0.5&cy=0.5)