Car

The critical role of lubricants in boosting F1 performance and reliability

by Samarth Kanal

8min read

Oil flows through every facet of a Formula 1 car, lubricating the engine, gearbox, suspension, and even wheelguns.

Car, Innovation, Future

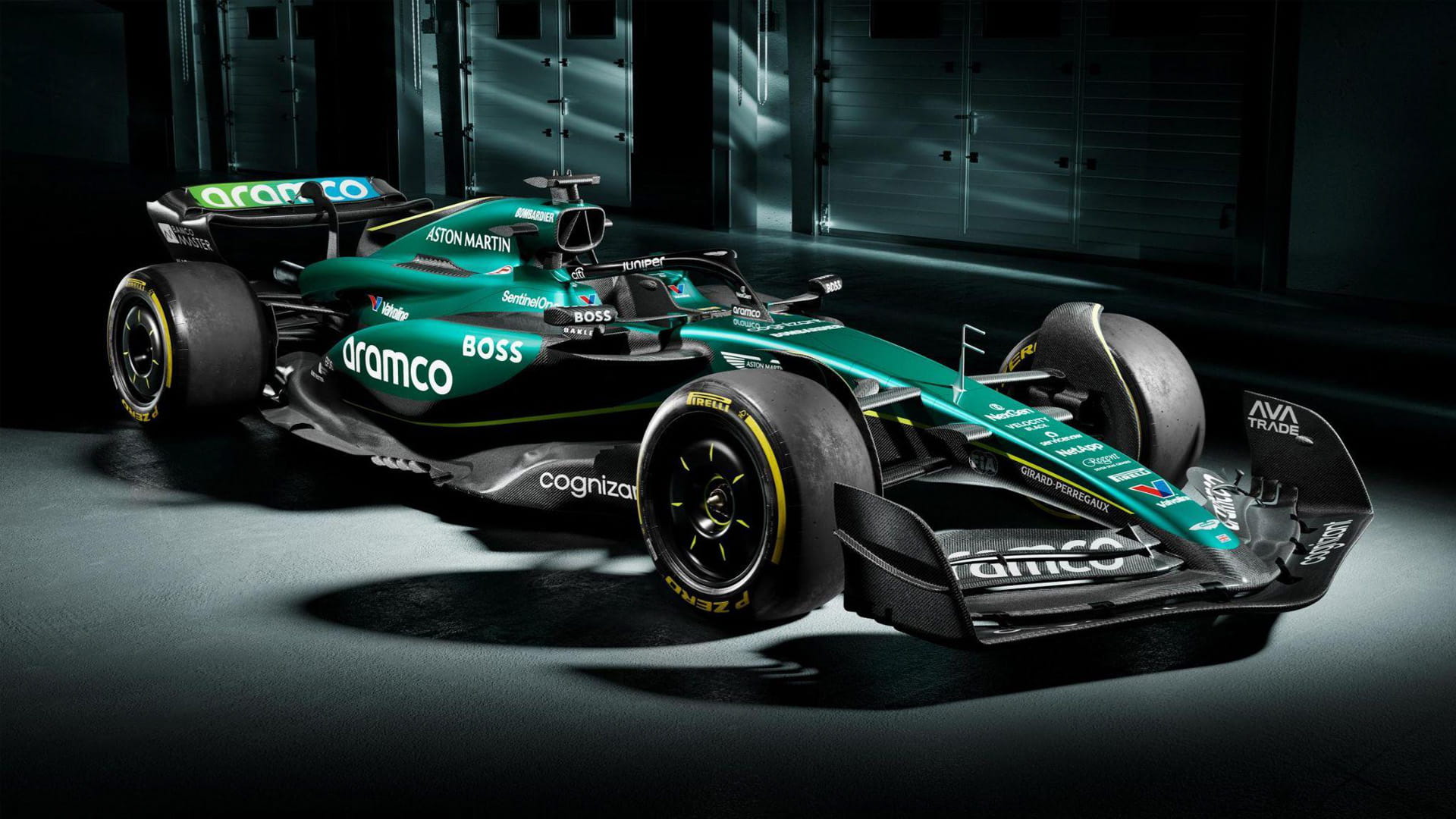

Formula 1 lubricants: why are Valvoline’s products so important to Aston Martin F1 Team?

F1 engines rev up to 15,000 RPM and combustion chambers within those engines reach temperatures of more than 1,000 degrees Celsius. That’s searing heat and intense friction - two factors that can cause terminal damage to moving parts like the crankshaft, pistons, and valves.

Suppliers don’t just provide lubrication, but various greases and thermofluids to F1 teams.

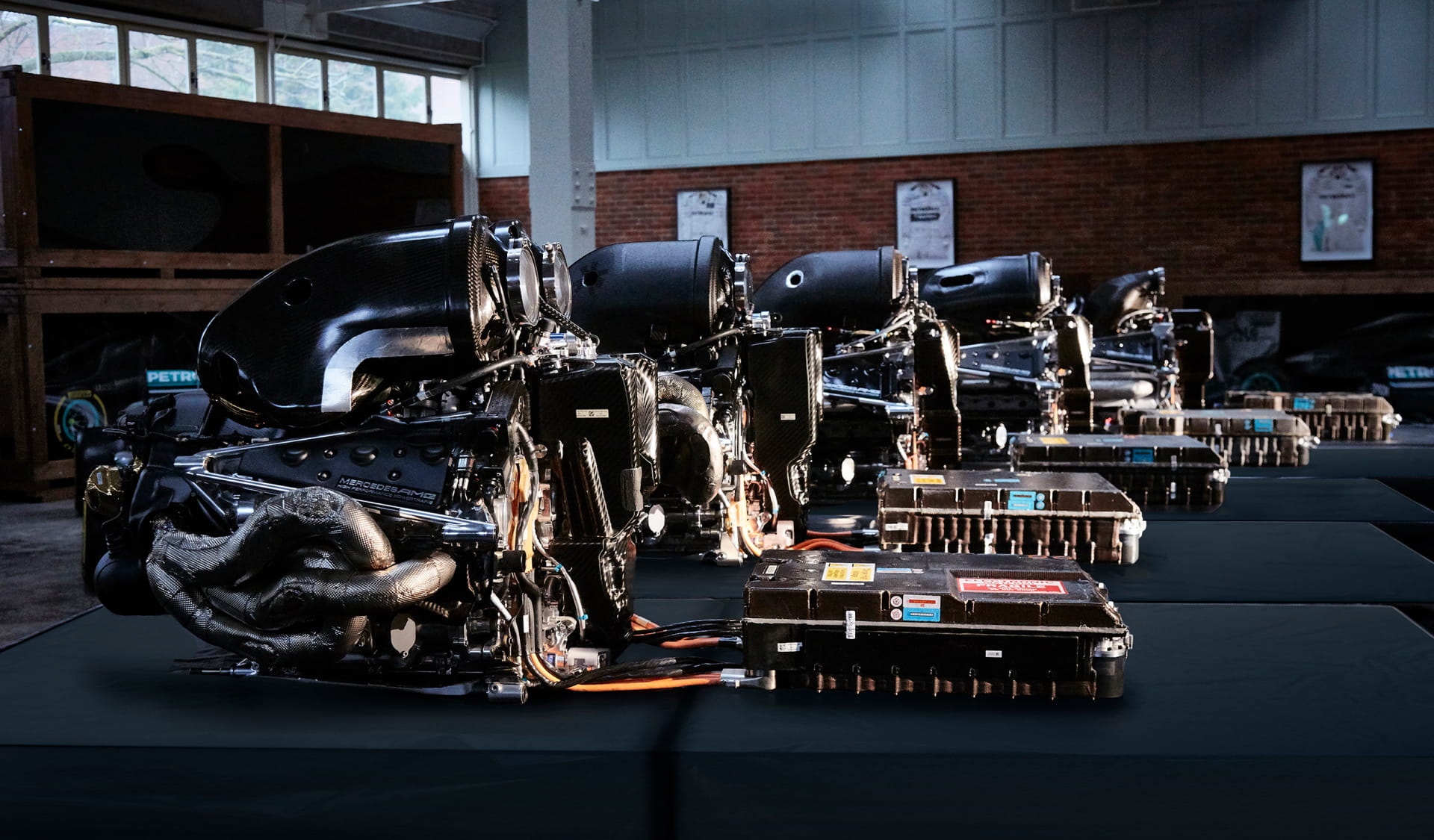

Petronas supplies Mercedes-AMG with lubricants in Formula 1, while Shell supplies Ferrari and Mobil 1 supplies Red Bull

Protecting an F1 car

Protection is the utmost priority of F1 lubricants, and it’s within the combustion engine that this process is perhaps clearest.

That heat could cause metal parts to expand and break, leading to terminal damage to the engine, but it can also cause some parts to fuse together.

Lubrication follows a complex path through the engine of a car. It is sent from the oil tank - using a pump to ensure oil is being delivered even while the car is cornering or on a slope - and then filtered on the way into the engine.

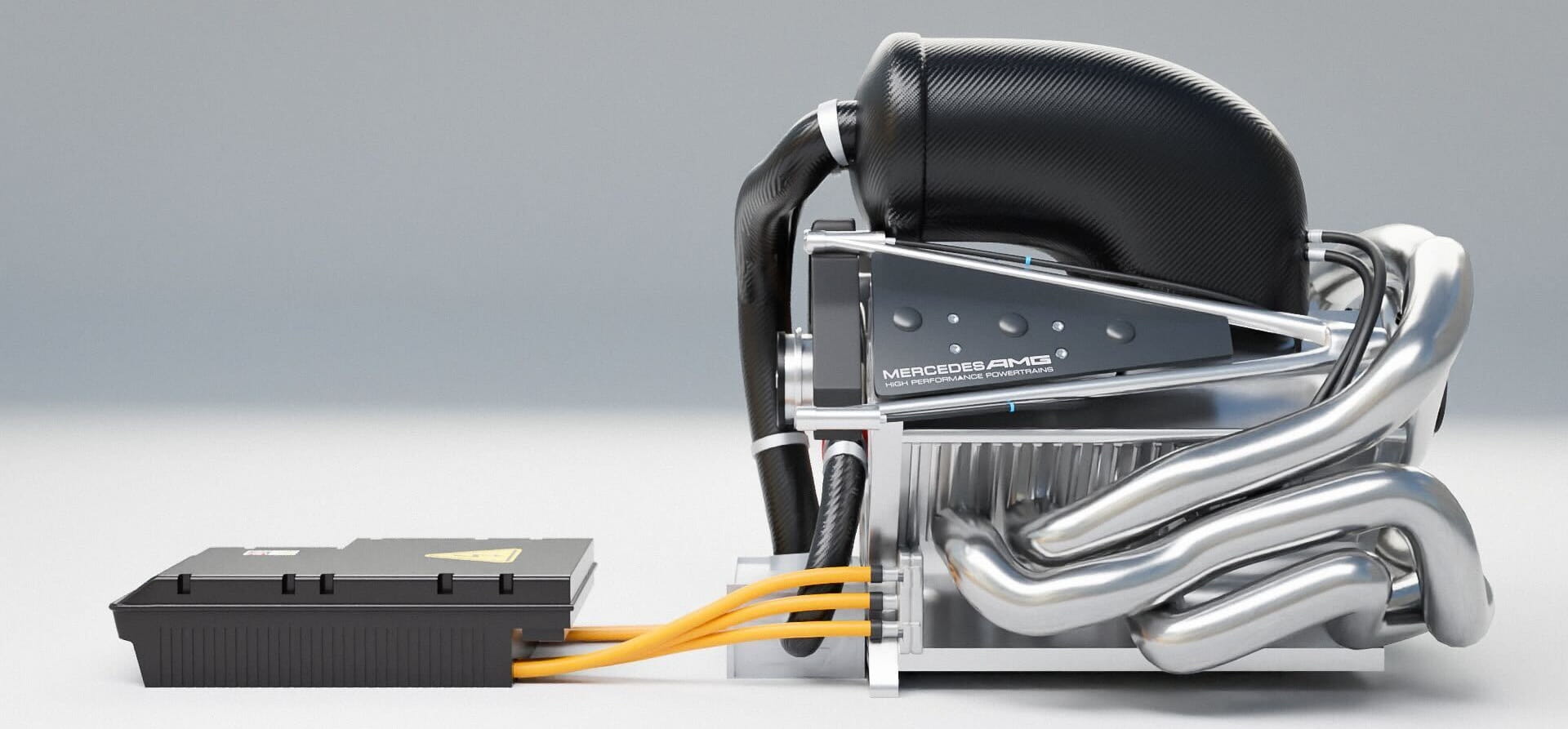

A 3D render of a Mercedes Formula 1 power unit. Lubricants affect every part of the power unit including the battery (L) and the turbocharger and combustion chamber

It’s not just the engine that benefits from friction and heat protection, but various other components of the powertrain including the gearbox. Like the engine, the gearbox undergoes high load at high speed, but generates high torque, and high temperatures.

“The oil has two functions: lubricating areas with contact, like gears and bearings, and cooling. Oil is always flung away from where we want it. Part of the gearbox design ensures the oil is put exactly where needed and is picked up under all conditions to be taken to a cooler and then back into the gearbox. On track, with big G-forces, the oil moves around the gearbox, and we have to account for that.”

.jpg?cx=0.5&cy=0.5)

The 2025 Mercedes Formula 1 steering wheel with the clutch paddle highlighted in purple

“We clamp those plates together, they begin to transfer torque and in doing so generate an immense temperature. Within about two seconds, the clutch is fully closed. The car is doing 100km/h and the driver hopefully is flying by his rivals.”

The Energy Recovery System (ERS) battery that stores energy from the MGU-K (Motor Generator Unit-Kinetic) and MGU-H (Motor Generator Unit-Heat) and allows drivers an extra boost of power also needs to be cooled using a dielectric fluid of high thermal stability - a coolant that does not easily conduct electricity.

“The reason we do that is to ensure the efficiency of the battery. We need the battery to be working at its most efficient to provide the performance exactly when the driver needs it.”

.jpg?cx=0.5&cy=0.5)

A 3D render of a Formula 1 ERS system delivering a boost of power to the rear wheels

Lubrication’s role beyond the F1 powertrain

Lubrication’s usefulness doesn’t stop at the engine, gearbox, and ERS. Even pitstops can benefit from specialist oils.

“Wheelguns have an oil spray that goes straight into the air supply that powers the gun. Wheel nuts have an anti-seize lubricant on their threads to ensure the pitstop process is as quick as possible when it comes into contact with the wheel gun.

“We want to reduce pitstop times, which can be the difference between gaining or losing positions on the track. This development is ongoing as we continue to collaborate with Mobil 1’s expertise. We have been partners since 2017 and continue to explore how we can achieve the best together.”

Red Bull uses specialised lubricants and greases to cut its pitstop times - and save time in a race

“A driver wants immediate reaction [from DRS],” said Mercedes F1 Team project leader Salvatore Schembri. “When you push the button, the flap needs to go down and up. The hydraulic system will guarantee this immediate reaction.

“We also need to guarantee full compatibility between the fluid and all the materials around the system and all the seals in order to guarantee full force reliability and guarantee, also on top of that, wear protection.”

A close-up look at the DRS actuator on the Aston Martin AMR25 Formula 1 car. The housing for the hydraulic system is under the ‘arm’ logo

The problem of parasitic loss

Oil pumps and hydraulic actuators can drain a small amount of power from the powertrain system. This is known as parasitic loss - a perennial tradeoff in formulating lubricants for cars, particularly high-performance ones.

“We always try to reduce this parasitic loss with every new generation of lubricants that we develop, so it's a constant driver of innovation - and always a challenge.

Red Bull’s Monaghan adds: “Lubricants are fundamental in balancing performance and reliability in Formula 1. On one hand, they maximise engine power and efficiency by reducing friction and controlling heat; on the other, they help ensure that critical components don’t wear out prematurely.

A Shell engineer testing lubricants for trace metals, viscosity, and other factors inside the Shell trackside laboratory

How long does it take to formulate an F1 lubricant?

Unlike aerodynamic parts, F1 lubricants can be reformulated throughout the season - although this doesn’t generally happen. F1 lubricants are honed over time and many teams now stick to tried and tested formulations using combinations of molecules closely governed by the technical regulations.

Each oil supplier also brings a trackside lab to the circuit to ensure that oil samples can be taken from a team’s engine within one minute and analysed within five minutes to see whether they are sufficiently lubricating the powertrain and related parts.

For Shell, which supplies lubricants and oils to Ferrari, that task is made easier given its long history with the Scuderia.

A Mobil technician using a spectrometer to analyse the components of a lubricant that has been extracted from an F1 car

“If we see something that is unusual, either we need to readjust viscosity - or it would be maybe a different task for Ferrari's engineers.”

Preparing for 2026 and beyond

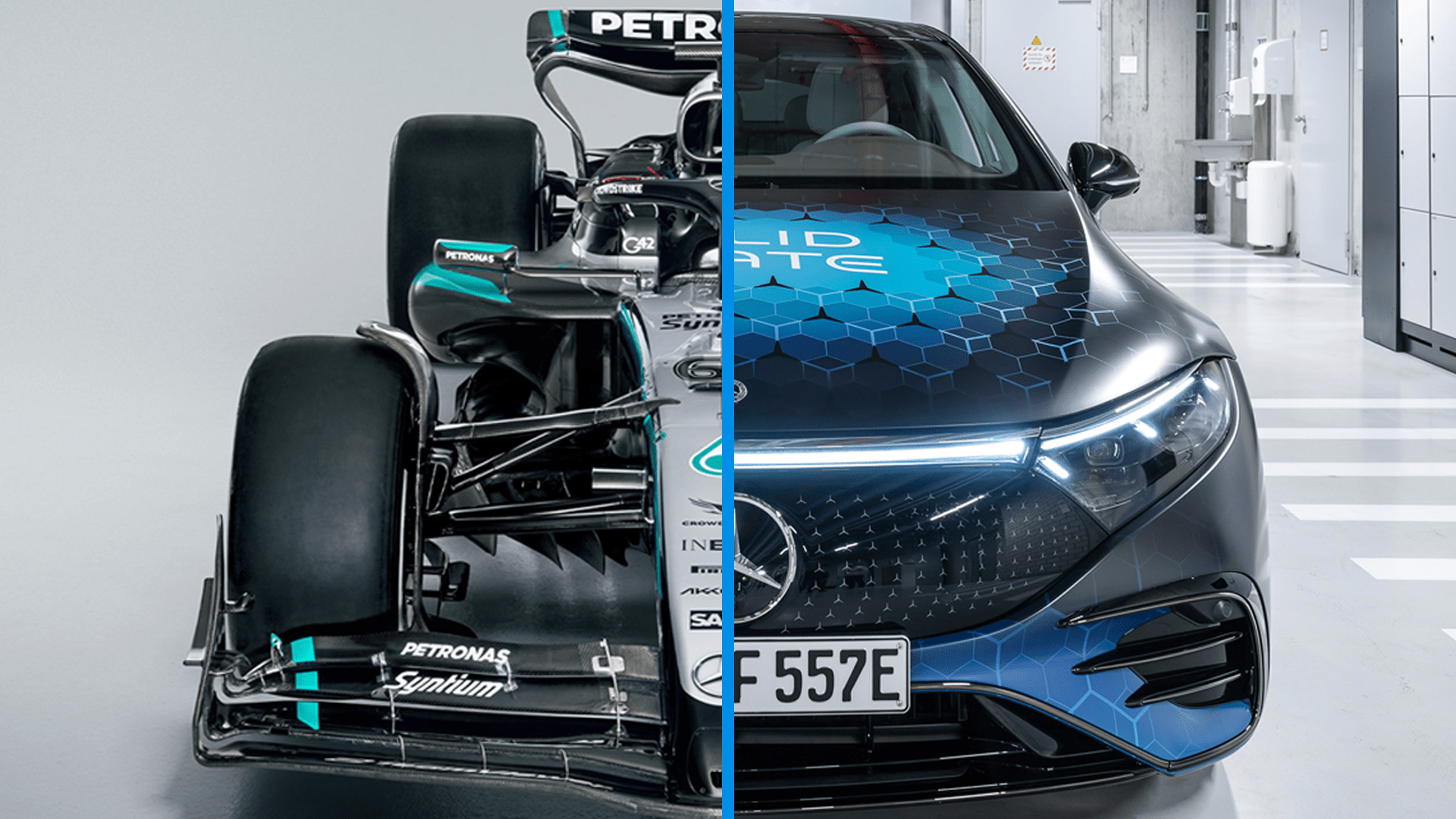

The 2026 Formula 1 engine regulations will bring significant changes to the power units - with a larger proportion of power being generated by the MGU-K and deployed by the ERS - but the combustion part of the power unit will still need sufficient cooling and protection.

“We have already used quite a lot of products from Valvoline,” says Aston Martin Aramco Formula 1 Team’s former team principal and now chief trackside offer Mike Krack.

.jpg?cx=0.5&cy=0.5)

Our 3D render of what the 2026 Formula 1 car could look like. A sweeping new set of engine regulations complements new aerodynamic regulations and the introduction of fuel that meets the FIA’s 100% sustainability requirements in 2026

Shell faces a similar task as it collaborates as closely as possible with Ferrari to formulate a new engine oil for 2026.

2025 Ferrari Formula 1 drivers Charles Leclerc and Lewis Hamilton inside the Shell trackside lab

From 2026, the MGU-K’s increased power output of 350 kilowatts (compared to 120kW prior to 2026) and the combustion engine’s drop of power output from 550kW to 400kW will present further challenges to lubricant suppliers as they account for the increased torque of the MGU-K.

/xpb_1314694_hires.jpg?cx=0.48&cy=0.64)

.jpg?cx=0.5&cy=0.5)

.jpg?cx=0.5&cy=0.5)

.jpg?cx=0.5&cy=0.5)