Innovation

Formula 1 helmets: How F1 helmet technology has evolved over seven decades

by George Wright

7min read

Racing helmets are perhaps the single most recognisable piece of safety equipment in motorsport, let alone Formula 1. Over the years it has become such an integral part of motorsport that many drivers have taken to making their helmet and its design a core part of their identity.

While driver identification is one purpose of a helmet, its most important job is to protect the driver in the event of an accident. This requires striking a delicate balance between an outer shell which is strong enough to resist being pierced or crushed by debris or impacts, along with an internal structure which is soft enough to dissipate energy and cushion the driver’s head in a crash.

The challenge of meeting these criteria has seen helmet technology gradually refined and improved over time in order to meet the ever-increasing safety demands of the sport, moving from crude early solutions to today’s advanced carbon fibre pieces.

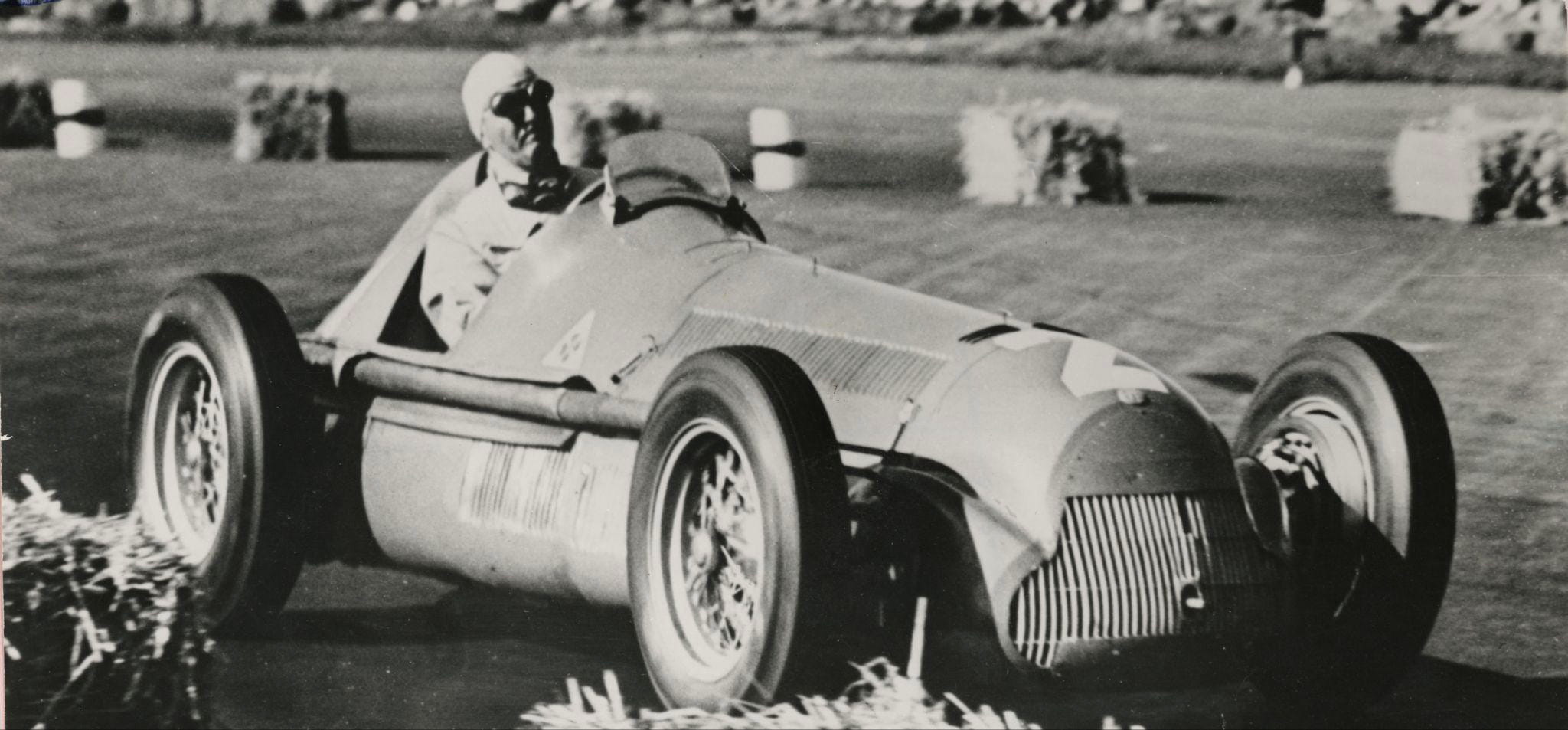

Nino Farina wearing goggles and a linen cap in the very first Formula 1 world championship grand prix at Silverstone in 1950

The early years of F1 helmets

When the F1 world championship began in 1950, there was already something of a split in attitude among the drivers when it came to the question of head protection.

Some - particularly older drivers who had been involved in racing before the Second World War - believed that the only headgear necessary was a simple linen cap and a pair of goggles to keep debris out of their eyes.

Others however did opt to use helmets, but they were a far cry from those we see today. In design they roughly resembled the kind of modern “hard hat” safety helmet you might see on a building site, covering only the very top of the driver’s head.

The materials used were also quite unlike today’s advanced composites. Instead, early helmets were primarily constructed from cork, which provided a modicum of energy absorption, while a hard lacquer outer shell went some way towards resisting piercing or crushing in the event of an accident.

In the context of modern helmet designs, these early helmets offered very little protection. At the time they were relatively state-of-the art, and a clear improvement over the cloth caps preferred by some drivers. The FIA soon recognised that they were a necessary safety measure too, and mandated their use starting in 1952. This rule has remained in place ever since.

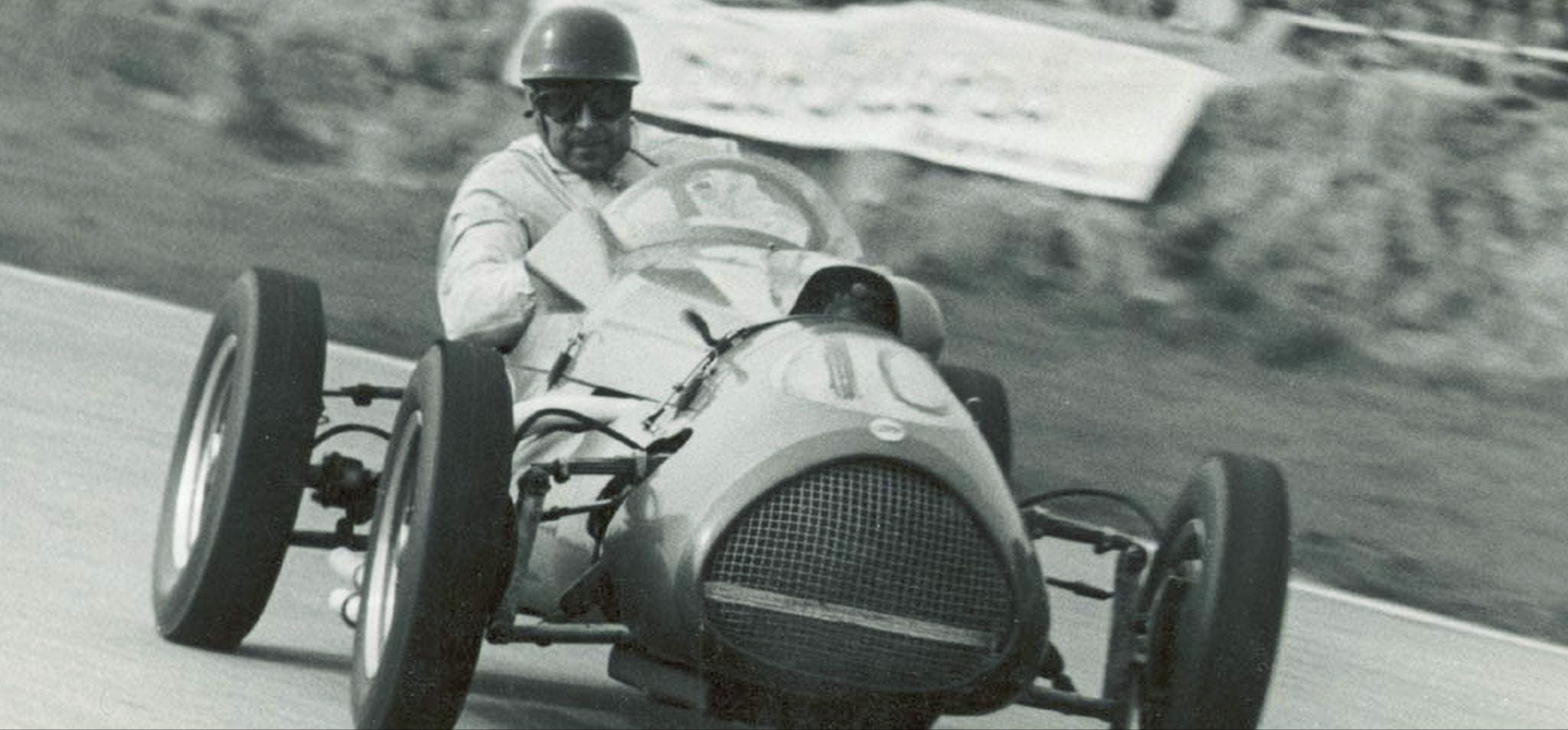

Driver Alan Brown wearing more formidable head protection in 1952 at the wheel of a Cooper F2 car

Mike Hawthorn’s racing helmet featuring an integrated visor - a novel technology in the mid-1950s

Disruption and innovation in the late 1950s

Despite the FIA's mandate, there was relatively little innovation in terms of the technology behind the helmets in the early 1950s. Cork and lacquer remained the state-of-the-art, and the only notable development was that some drivers began using helmets with integrated visors which removed the need for goggles. Mike Hawthorn, 1958 world champion, was one notable user of this solution on his cork Everoak helmet.

The world of F1 helmets was ripe for disruption and innovation, which finally came right as the 1950s gave way to the ‘60s.

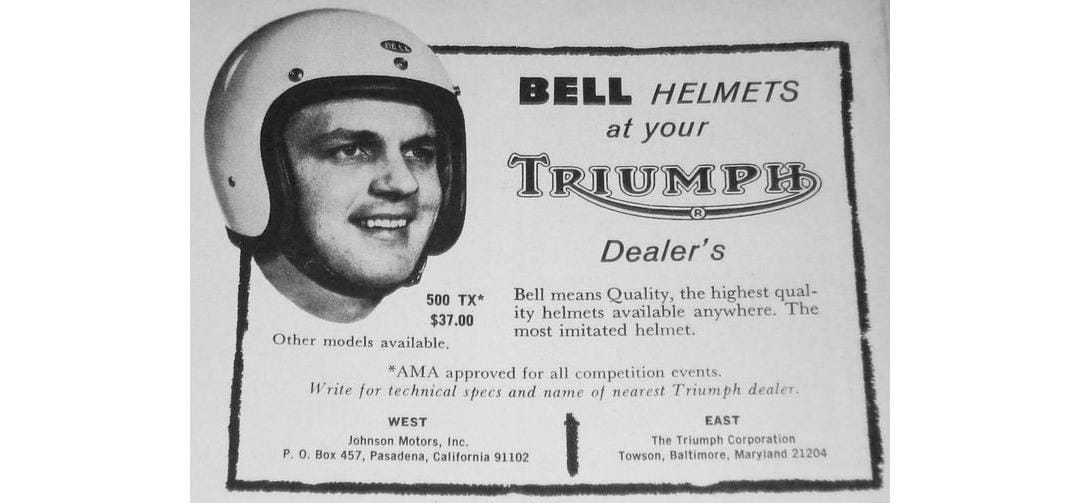

One key player behind this upheaval was US firm Bell Helmets. In 1954 it launched a purpose-built helmet and in 1957 it launched the first ever helmet specifically designed and safety certified for motor racing, with protection for the rear and much of the lower half of the driver’s head.

Its construction was equally revolutionary, with a hard fibreglass outer shell in place of the lacquer on older helmets, nylon, and expanded polystyrene - a material still used in modern helmets - in place of the old cork liner.

These materials proved far better suited to the tasks of protecting against impacts and dissipating energy in a crash than older helmet designs.

An advert for the innovative 1957 Bell 500 TX helmet - image courtesy of Bell

The move to full-faced helmets

Bell followed this innovation with another much-needed improvement.

While fibreglass helmets were a notable step up from previous cork designs, one flaw which was soon apparent was that they still did not protect the driver’s face.

Drivers such as Dan Gurney had long complained about stones and debris pelting his face during races, and his point was only emphasised further by the death of Lotus driver Alan Stacey in 1960 when he was hit in the face by a bird at the Belgian Grand Prix.

Bell soon devised a solution - a full-face helmet with a solid fibreglass chin section and an integrated perspex visor, which did away with the need for goggles.

The full-face helmet had initially been intended for dirt-motorbike riders, but after seeing one in use Gurney decided to use it in F1 at the 1968 German Grand Prix.

His fellow drivers were initially sceptical, fearing that the visor would fog and leave them unable to see. Gurney’s example, and development of anti-fog coatings by Bell soon put paid to this concern however, and drivers duly flocked to the new improved helmet design. A driver - Clay Regazzoni - wearing an open face helmet won for the final time just under two years later in 1970, and by 1975 they were gone from F1 entirely - with Finnish driver Leo Kinnunen the last F1 driver to have used an open-faced helmet.

Dan Gurney wearing a full-face helmet at the wheel of the McLaren M14A in 1970

Refining the helmet formula with tear-offs and materials

The overall form-factor used by Bell’s first full-face helmet was such an improvement on what had come before that it is still in use today. However, there was still room for development when it came to improving materials, or more subtle areas of the design.

Two key concerns in particular arose which designers would need to meet: visibility and fire protection.

When it came to visibility, drivers were concerned about the possibility of oil or dirt coating their visor while racing.

Some took cloths with them in the car as a solution, but helmet manufacturers devised a more advanced system of tear-off strips of plastic over the helmet’s visor, which could easily be removed by the driver if their vision was obscured.

This system experienced some early teething issues.

For example, at the 1971 Italian Grand Prix when race leader Chris Amon inadvertently ripped his entire visor off while trying to remove a tear-off. Such problems were soon ironed out through stronger visor mountings and more advanced adhesives however, and tear-offs remain present in F1 to this day as a result.

.jpg?cx=0.5&cy=0.5)

Pierre Gasly’s helmet for the 2023 United States Grand Prix with visor tear-off grips attached. The inset image (top-right) is a visor on the ground after a driver has ripped it off their helmet

Fire proved a far more pressing concern, especially as the fibreglass used in early full-faced helmets produced toxic fumes when burned.

Bell was among the first to debut a fire-resistant helmet in 1973, and the same period also saw helmets augmented with a medical air supply tube. This was mandated by the FIA after the death of Jo Siffert in 1971, and could help prevent a driver from asphyxiation from smoke and fibreglass fumes in the event of a fire.

More work was needed to make F1 helmets safer. When Niki Lauda’s car crashed and burst into flames at the Nurburgring in 1976, his helmet - manufactured by Italian firm AGV - flew off his head, leaving its protective measures useless. Lauda thankfully survived, but he carried the scars of that infamous accident.

Niki Lauda driving his Ferrari 312T in 1976

The introduction of Kevlar and the HANS device

Manufacturers rose to the challenge of improving safety. New players such as Japanese firm Arai entered F1 in 1976, while designs such as Bill Simpson’s distinctive “Bandit” helmet briefly gained favour.

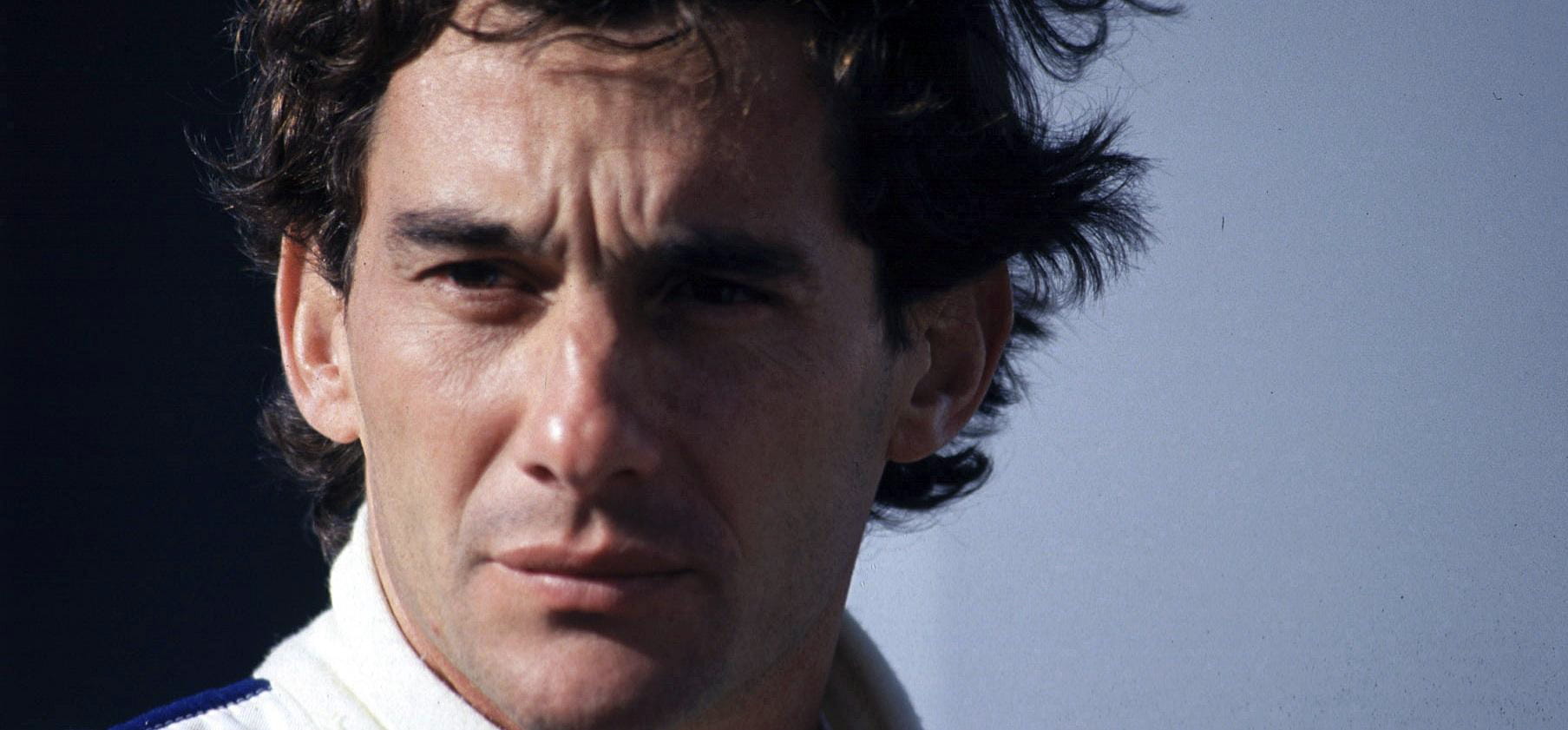

This notion was shattered in the most tragic possible way by the 1994 season, which saw the deaths of both Ayrton Senna and Roland Ratzenberger, as well as several other serious injuries for the likes of JJ Lehto, Rubens Barrichello, Karl Wendlinger and Pedro Lamy.

The high-profile death of Ayrton Senna at San Marino in 1994 was one of many serious accidents that year

F1 and the FIA responded by pushing safety standards to new heights, and helmet manufacturers played a key role in this.

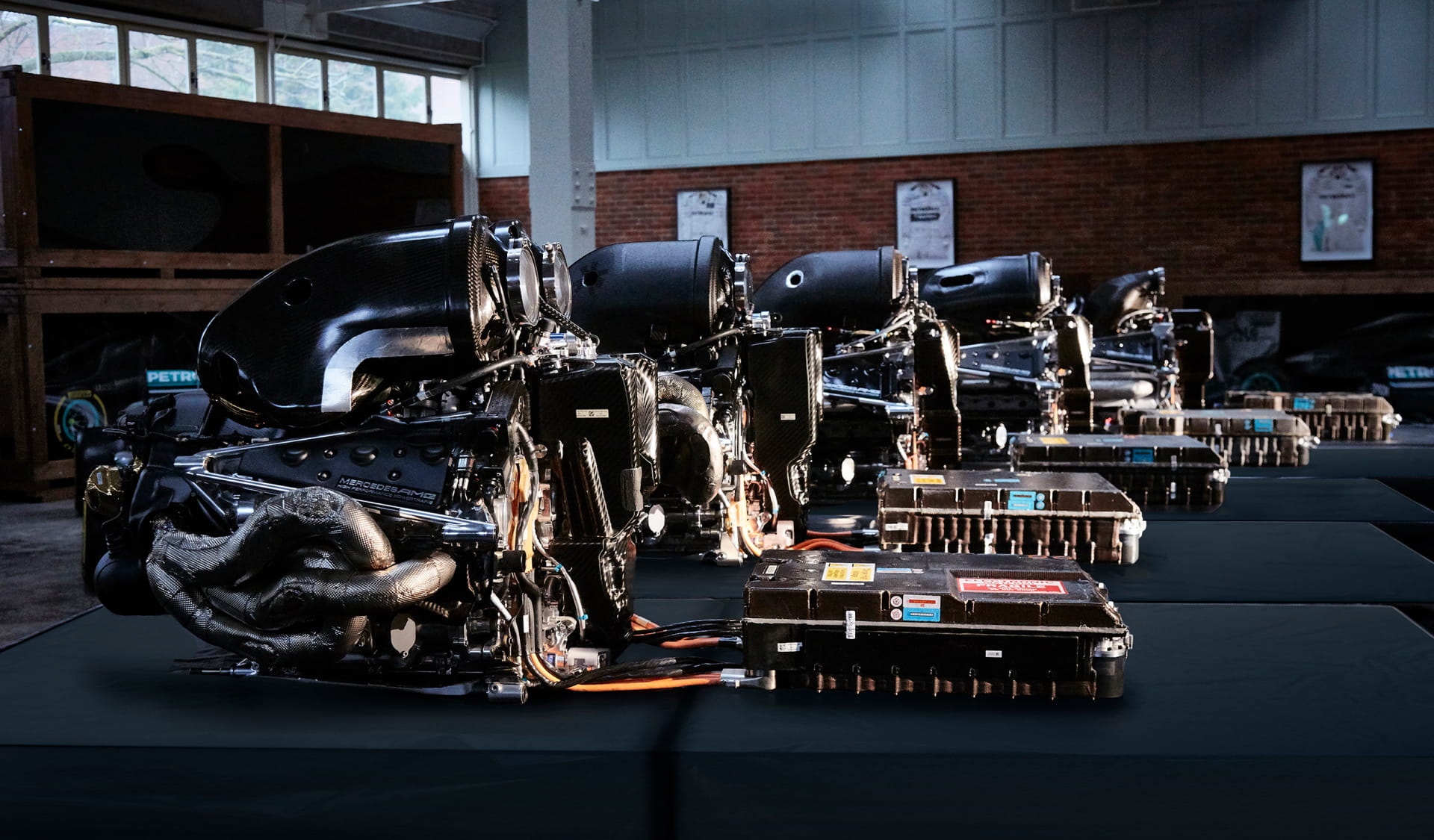

In 2001, Kevlar composite helmets were replaced with full multilayer carbon fibre outer shells - the same material used in the chassis of F1 cars. The improvements in resilience which came with this change were enormous, with a 30% improvement in resistance to penetration, and a staggering 70% improvement in energy absorption. Not only that, but the material change also had the added effect of reducing the overall weight of the helmet, which lessened the strain placed on a driver’s neck by g-forces through accelerating and decelerating.

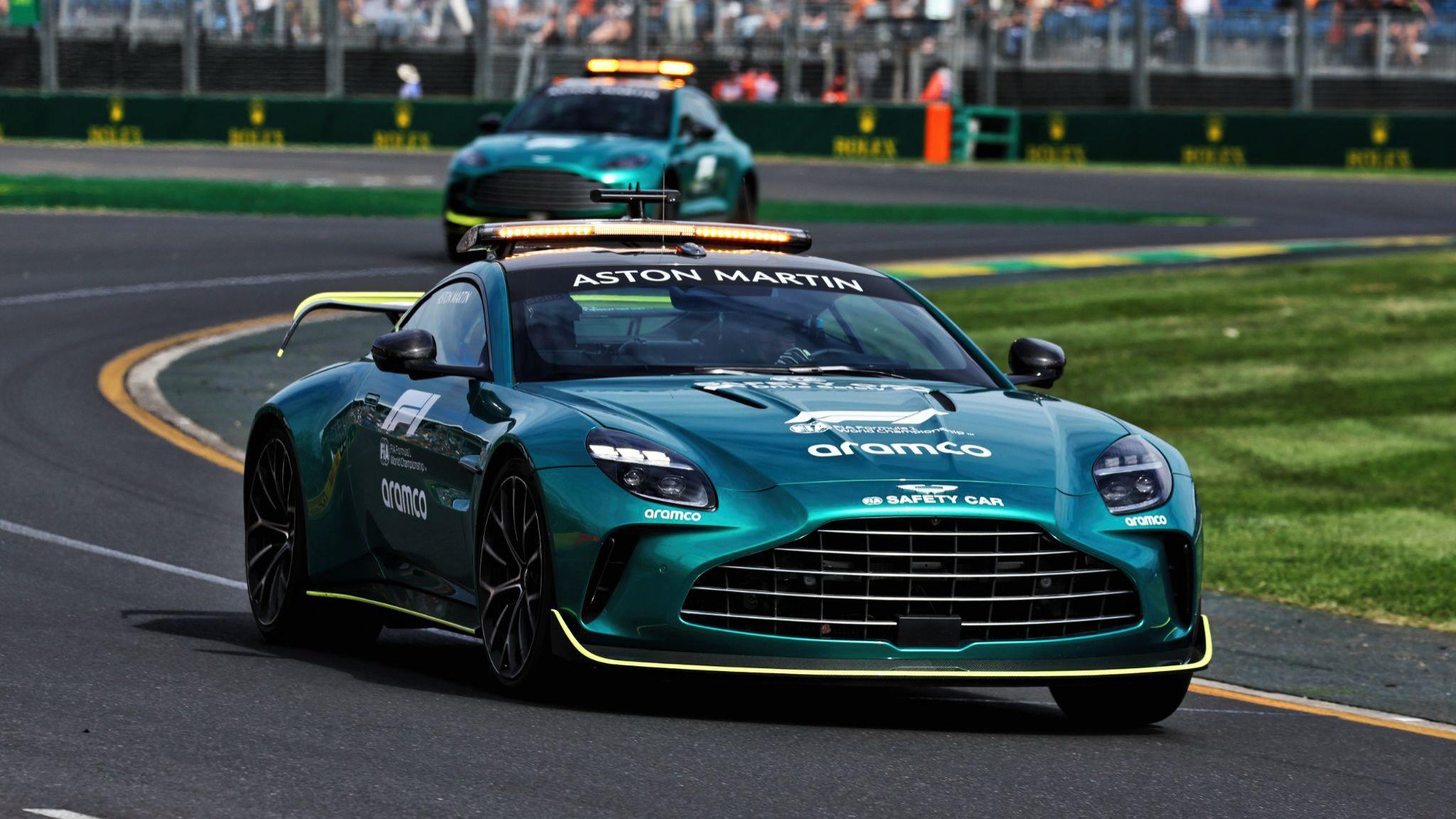

This was further augmented with F1’s mandatory introduction of the head and neck support (HANS) device in 2003 after extensive testing by Mercedes from 1996-98. Mercedes had also tested an ‘airbag’ but found that the HANS device was far more effective.

This device is worn over the driver’s shoulders, and connected to their helmet to prevent erratic head movements which could lead to a type of injury called a basilar skull fracture, often encountered in cases of rapid deceleration such as a F1 crash.

The HANS device was designed by Dr Robert Hubbard in the 1980s and early tests showed that, in the event of rapid deceleration, it dissipated energy on the head and neck by up to 80% while also reducing neck compression significantly.

The death of NASCAR driver Dale Earnhardt Sr. in 2001 sparked renewed interest in the HANS device, although previous fatal accidents for drivers such as Ratzenberger, Bill Vukovich, and Greg Moore had already shown the need for head and neck protection. Some drivers were reluctant to use the device but now it is widely used across motorsport series.

HANS devices are primarily composed of carbon fibre polymers. They anchor the drivers’ head and shoulders via tethers and prevent the driver’s head from ‘whipping’ and rotating in the event of a crash, while also restricting rotational head movement.

Aston Martin Aramco F1 Team driver Lance Stroll donning his race helmet with HANS device attached over his shoulders. It is tethered to the left and right of the helmet

A freak accident leads to a vital innovation

While helmets of the 2000s were incredibly strong by most standards - as was memorably demonstrated in 2004 when German firm Schuberth drove a tank over one of Michael Schumacher’s helmets - they still were not impervious.

In qualifying for the 2009 Hungarian Grand Prix, Felipe Massa was hit by a spring that was dropped by the Brawn GP car of compatriot Barrichello. This one kilogramme spring penetrated the polycarbonate visor of his helmet and left him with injuries that sidelined him for the rest of the season.

In response, the FIA issued new helmet specifications in time for the 2011 F1 season. These introduced a strip of a material called Zylon along the top of the visor to prevent projectiles piercing the weakest part of the helmet. Zylon’s tensile strength is 1.6 times that of Kevlar, and its addition was specifically aimed at preventing incidents such as Massa’s from happening again.

.jpg?cx=0.5&cy=0.5)

The FIA’s 2011 helmet specification showing the location of the Zylon strip above the visor along with measurements

This specification was further updated in 2019 by shrinking the overall height of the visor, and strengthening the area above the opening of the helmet, replacing that Zylon strip with an integrated strip of carbon fibre protection.

Compliance with these new standards is ensured through a series of 14 separate tests, including a ballistic test where a dummy spring is fired at the helmet at a speed of 250 km/h. All four major manufacturers - Bell, Schuberth, Arai and Stilo - have produced helmets capable of meeting or exceeding this standard, which undoubtedly makes them the safest helmets in F1 history.

If the development path of those helmets has shown anything though, it is that new challenges will always arise, and that improvements in safety are always possible.

Time will only tell what further revolutionary developments in helmet design might arise in the coming years.

.jpg?cx=0.5&cy=0.5)

.jpg?cx=0.5&cy=0.5)

.jpg?cx=0.5&cy=0.5)